productionManager

productionManager

Share

Collapsible content

Production Description

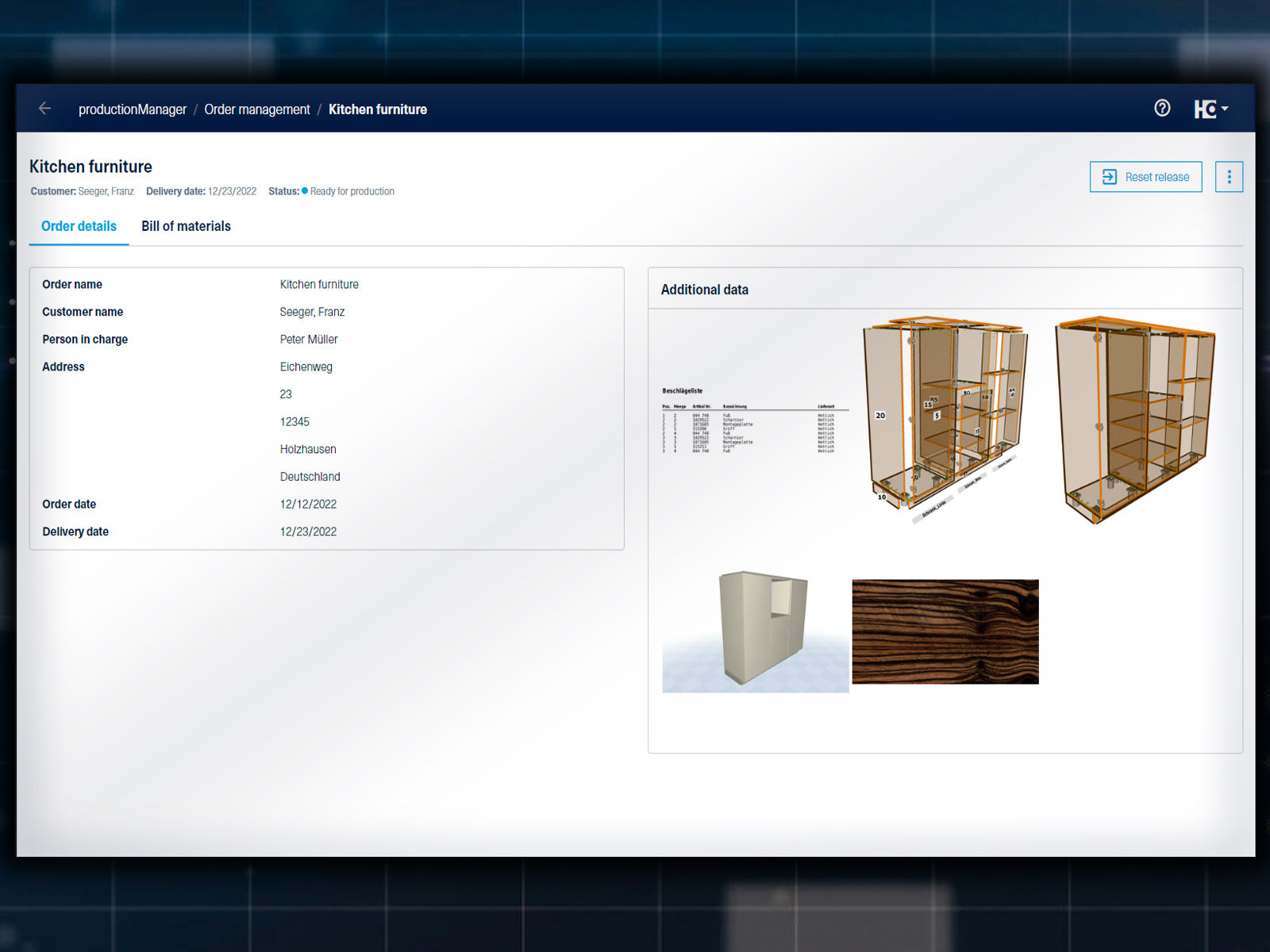

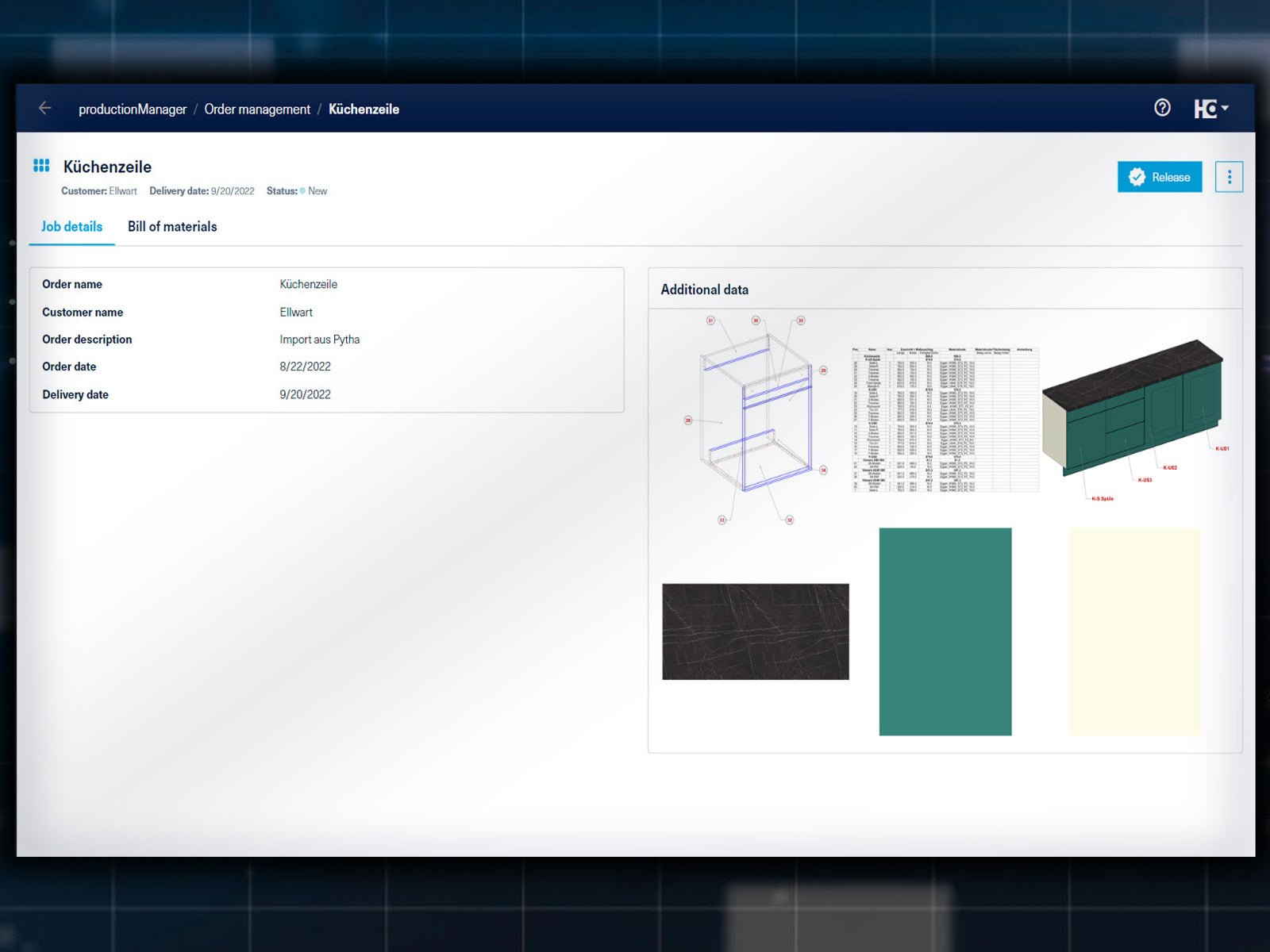

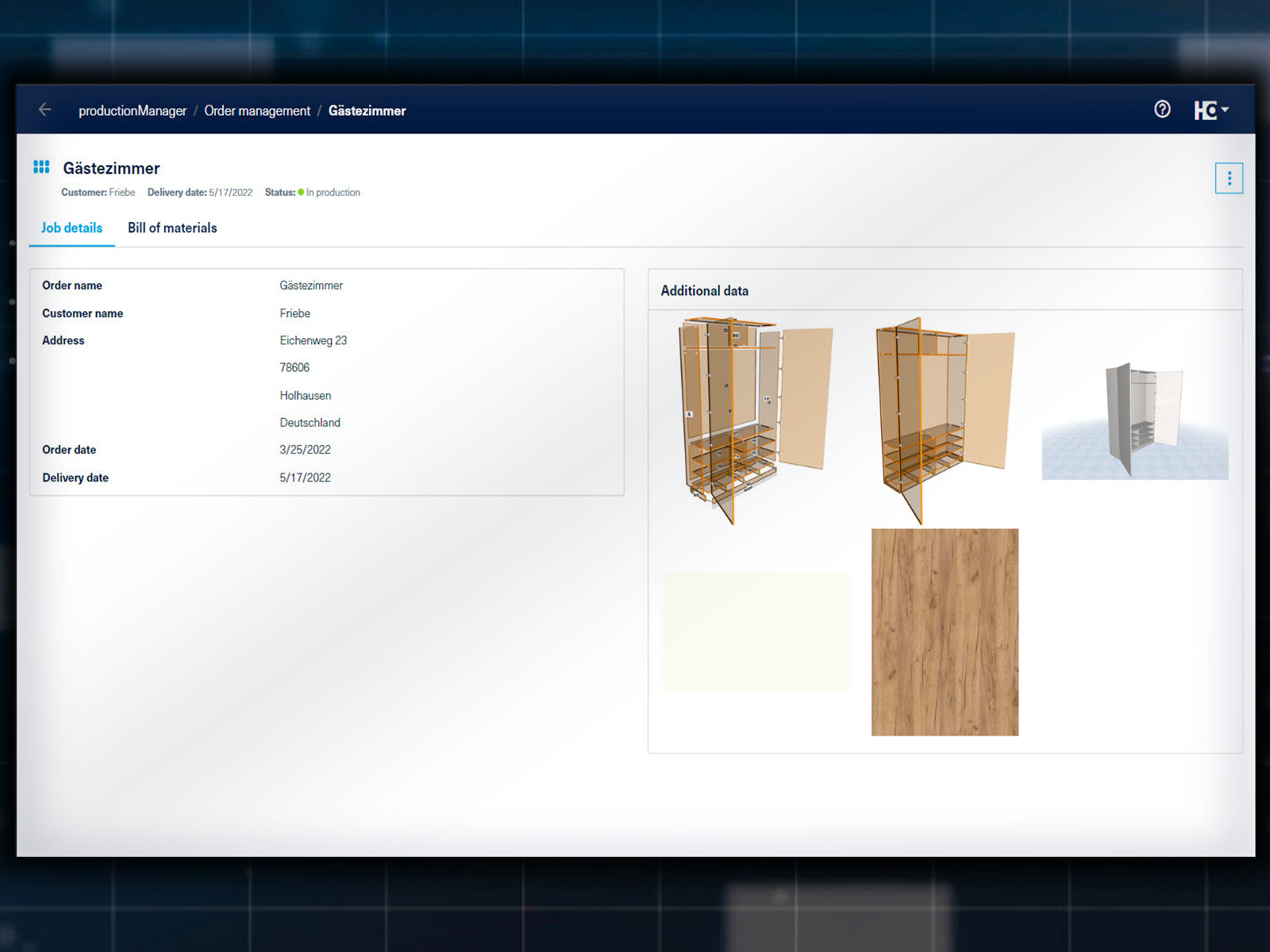

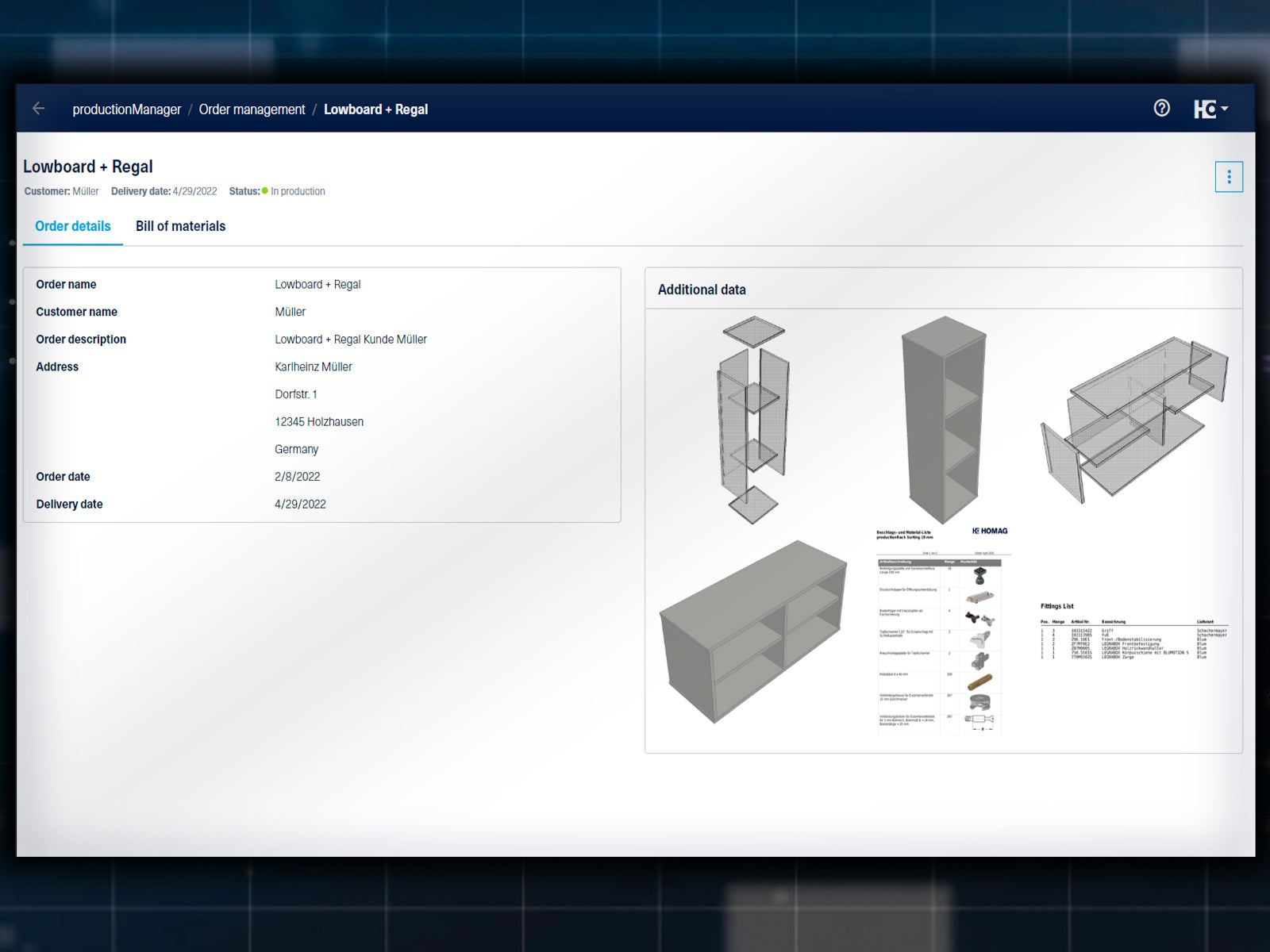

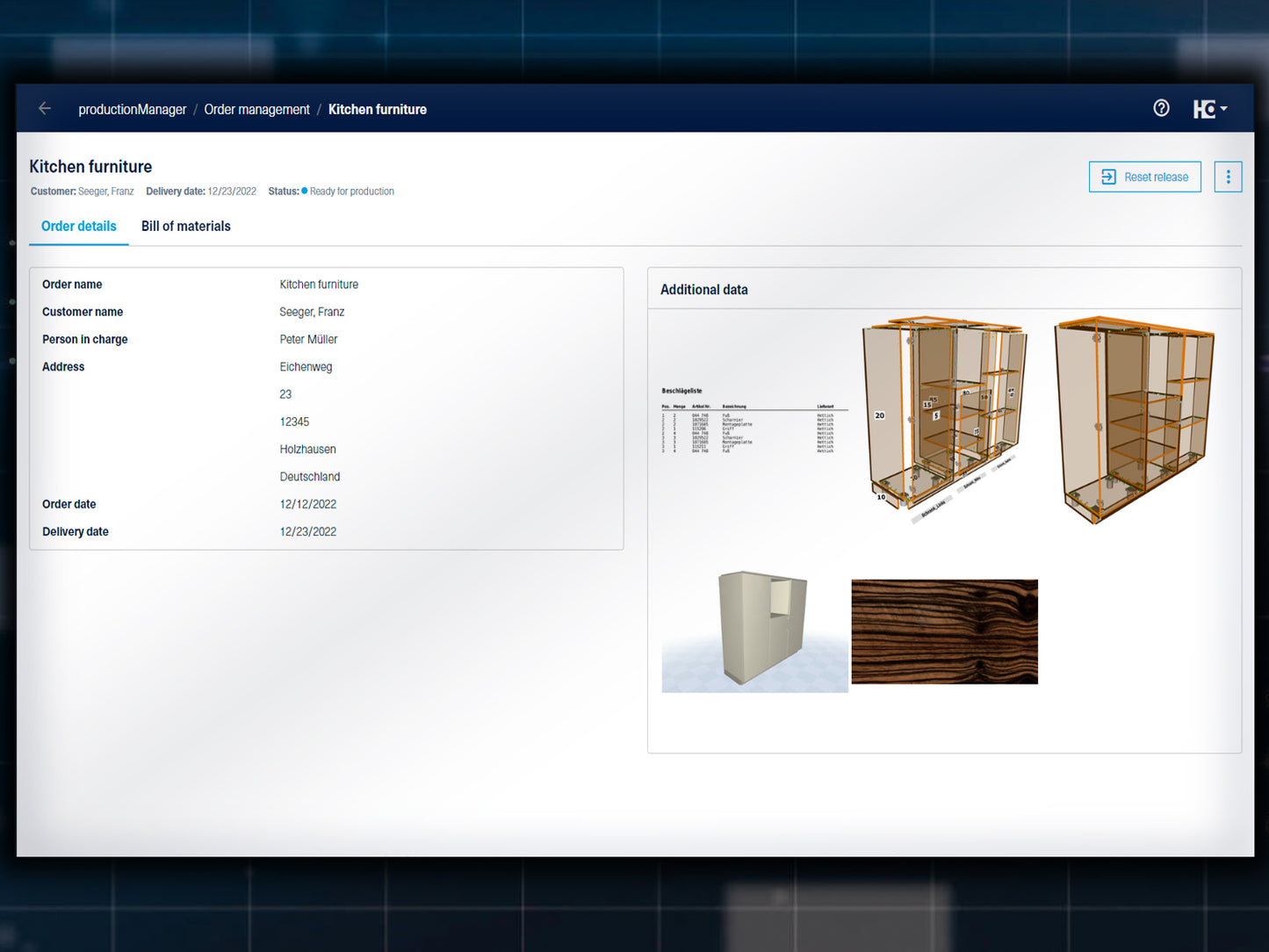

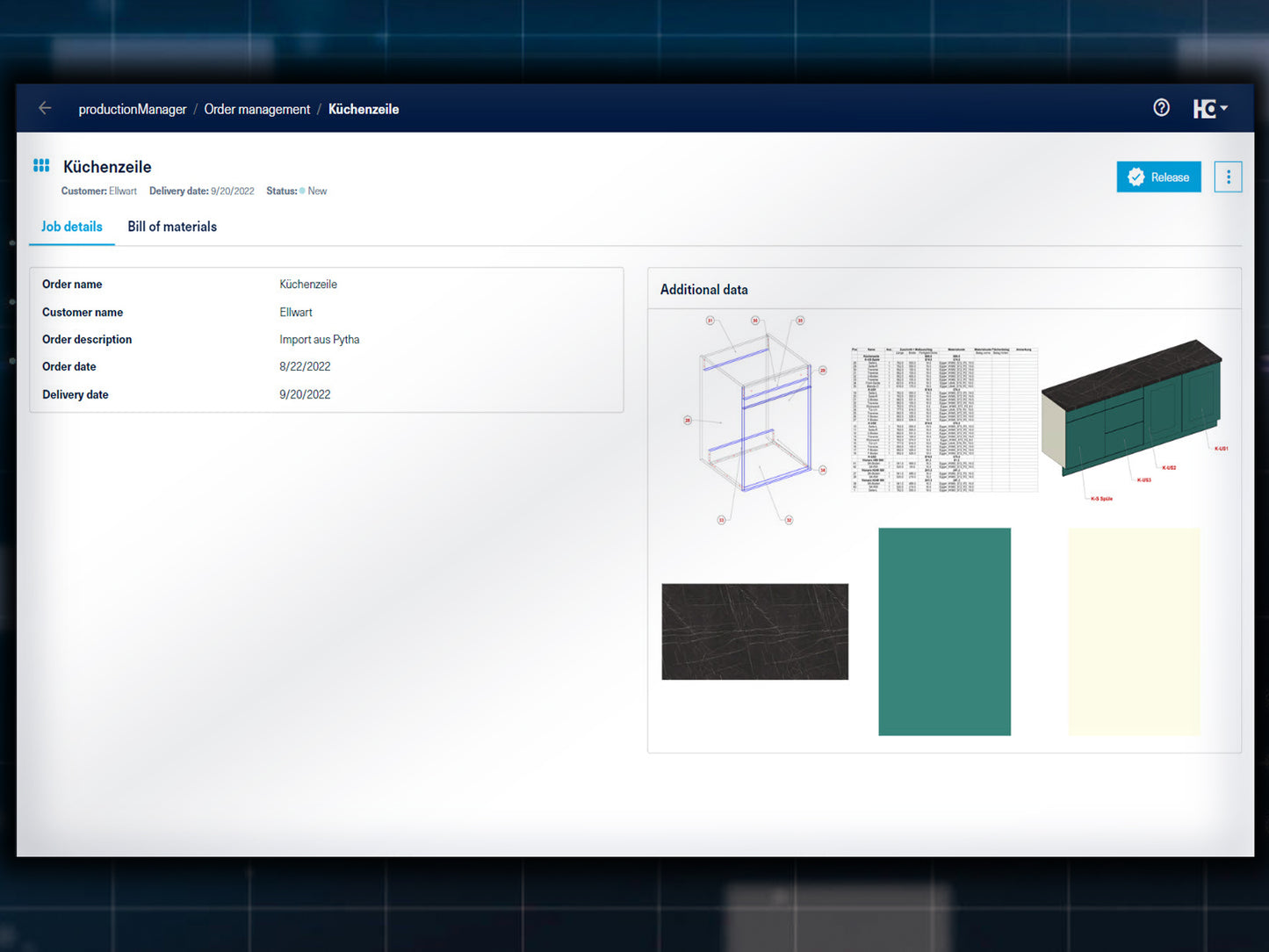

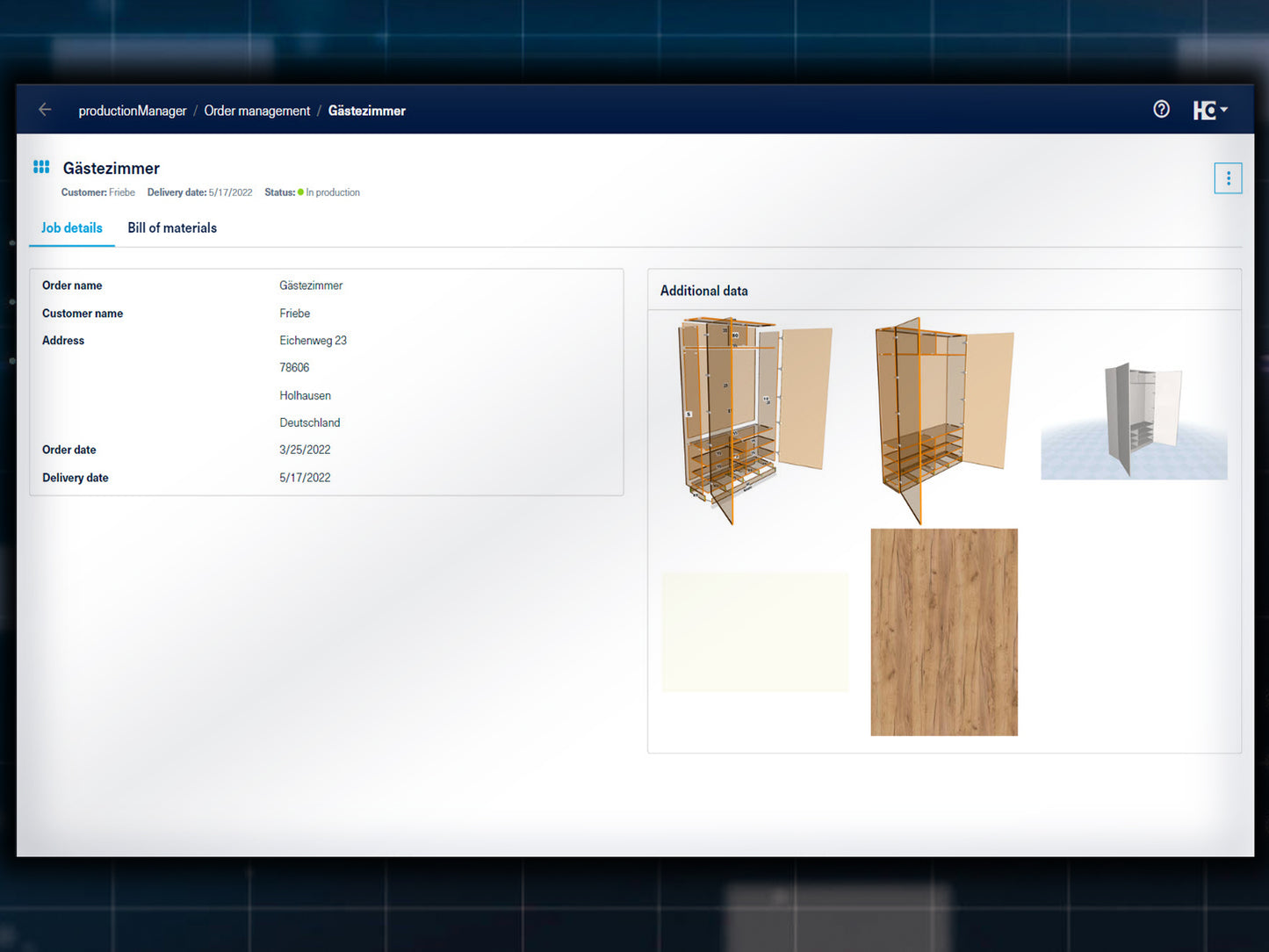

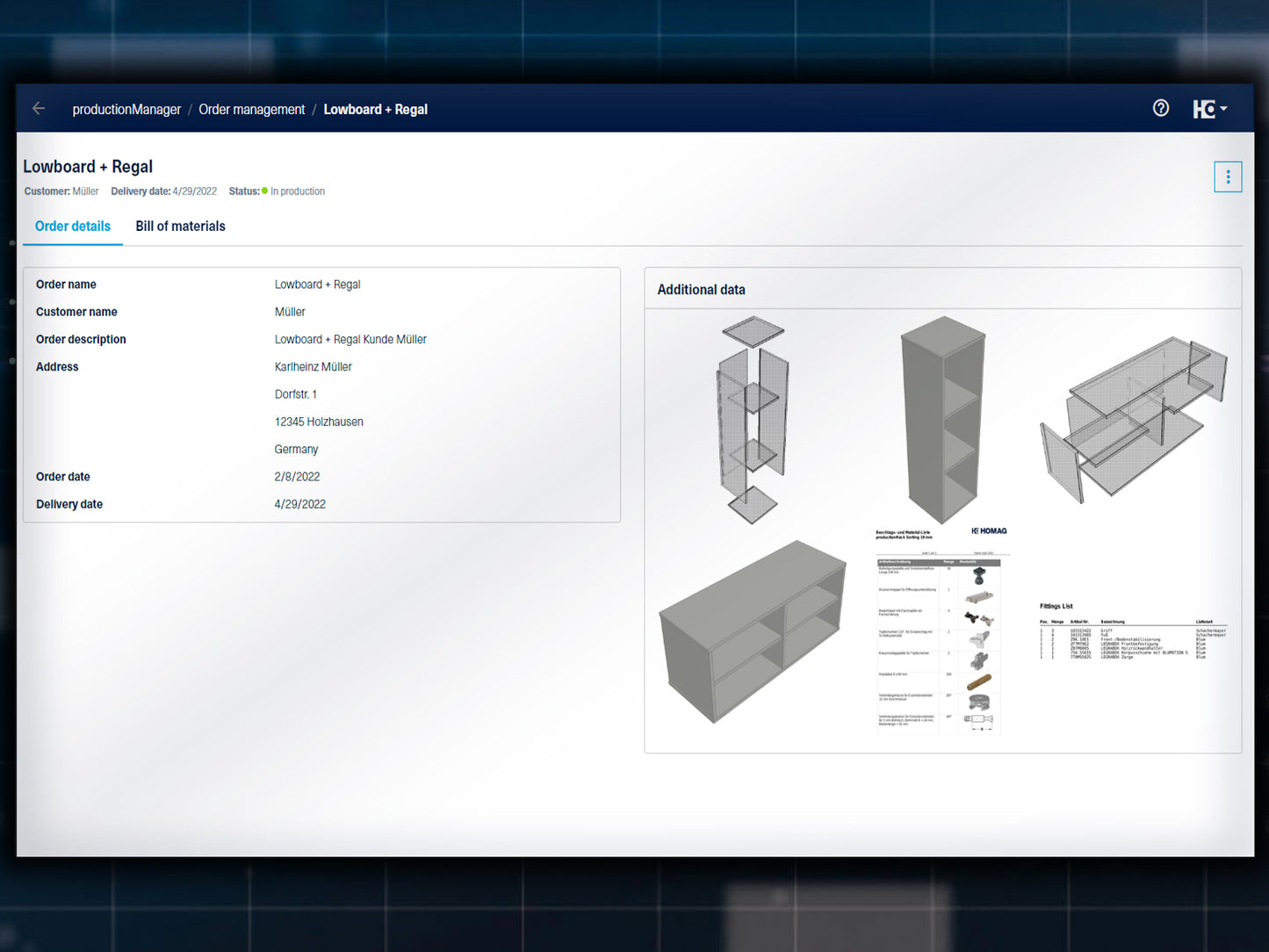

With full order books, the challenge of maintaining an overview and keeping order data and information up to date among all employees is growing. With the digital job folder, everyone on your team now has access to all information on every job in real time - from work preparation to production to assembly.

Highlights

Benefits

- Put an end to piles of paperwork: The "digital job folder" ensures the continuous digital use of planning and design data and can replace paper documents in production.

- Data import from different systems: Create a new order or

import it from a CAD/CAM system, an industry solution or Excel. Then all details are available digitally (articles, assemblies, components with drawings). - Complete transparency: All employees can track job progress in real time and view the status of articles and components.

- Flexible integration: productionManager can be easily integrated into any existing workshop environment. No adjustments to the software landscape or machinery are necessary.

- No investment costs: productionManager is completely free of charge in the Classic version.

- No update or maintenance costs: The web-based software is always up to date and no expenses for updates are necessary.

Simple and Intuitive Controls

Sanding Heads

Technical Details

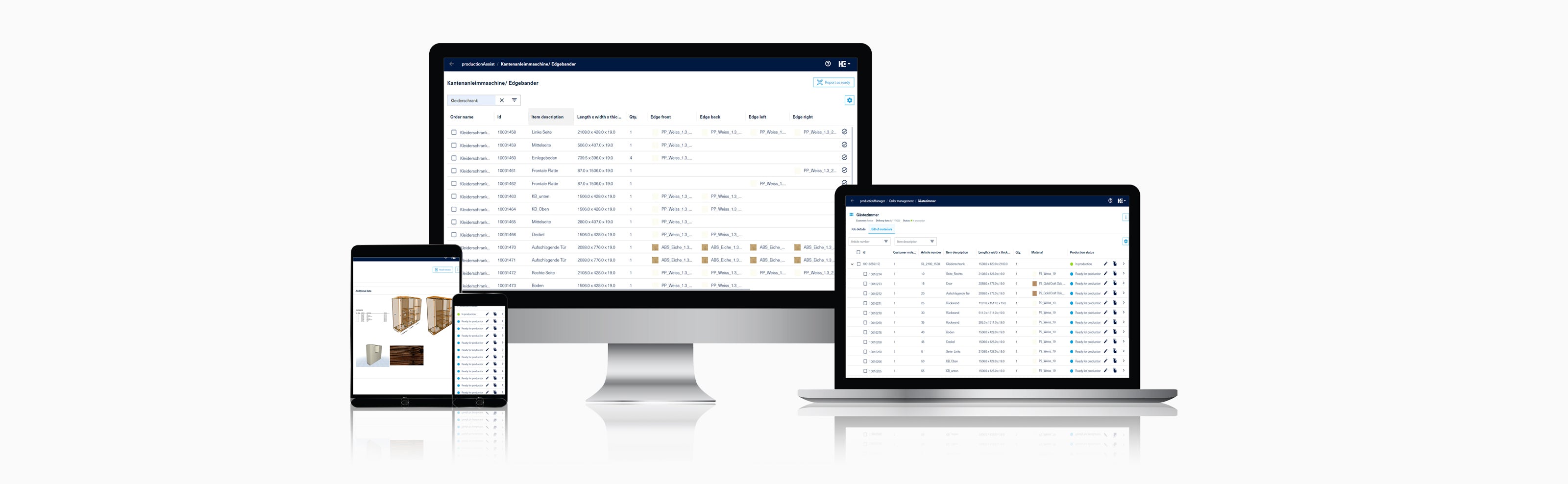

- The productionManager is a browser application for use on a PC, laptop or tablet

- For the use on the PC or laptop we recommend the browsers "Microsoft

Edge", "Google Chrome" or "Firefox" - Internet access (DSL, UMTS, LTE): at least 5 Mbit / recommended 50 Mbit

- Registration via tapio Login (tapio account required)

Features

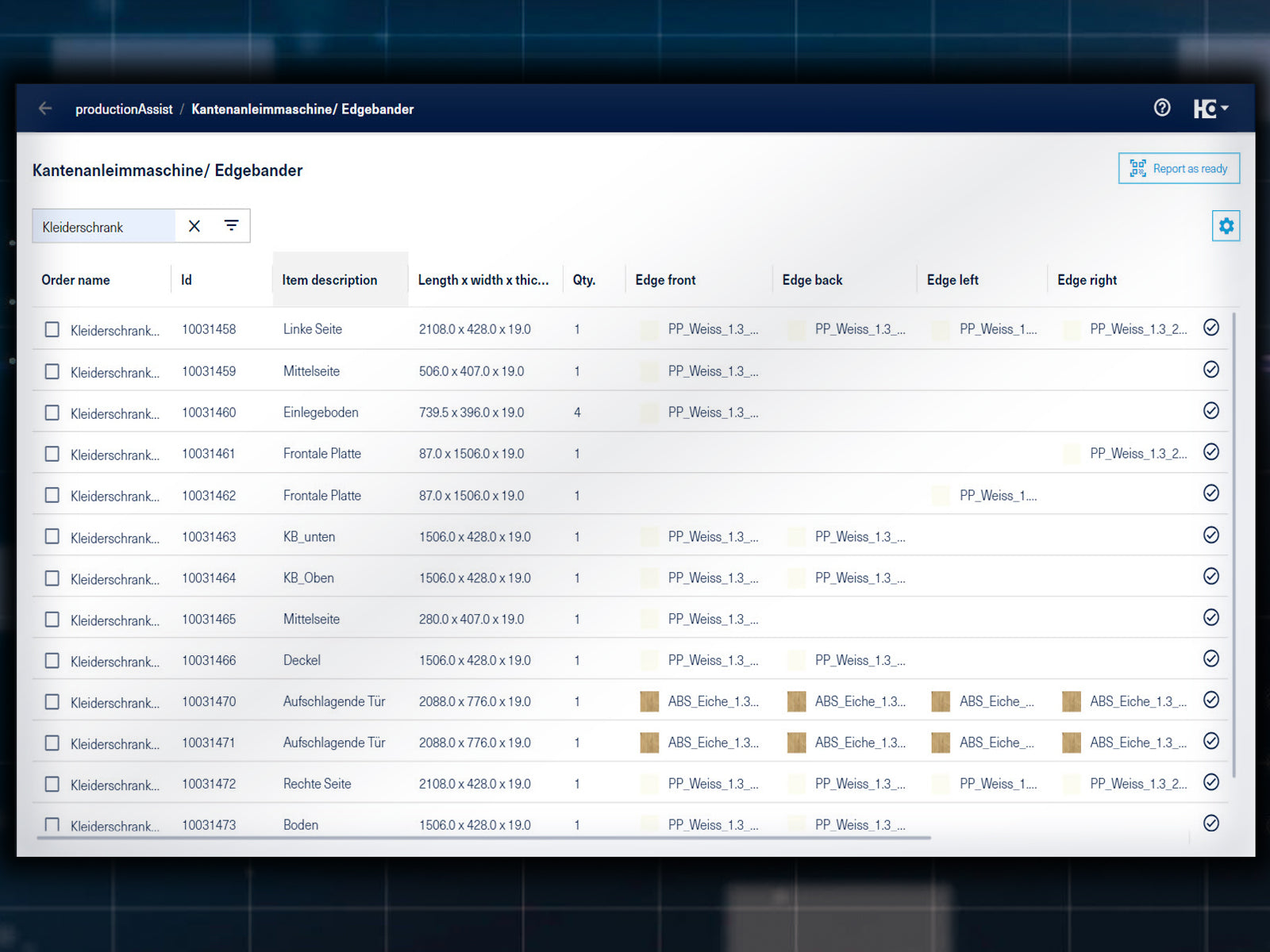

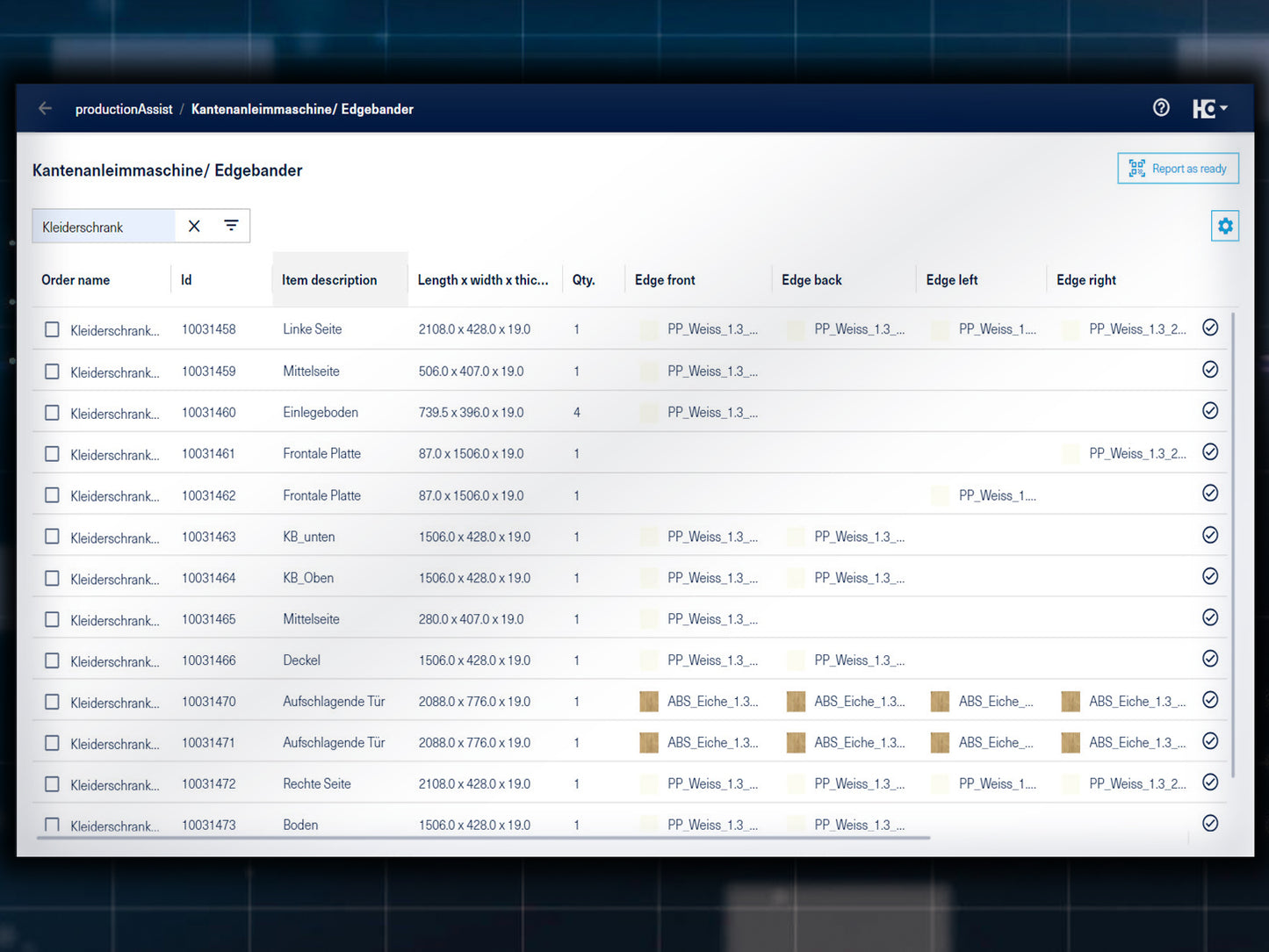

- Feedback on the status at various stations in the workshop: The included "productionAssist Feedback" app for the tablet displays the components and articles that are to be processed.

- Components and articles can be reported as "finished" by scanning or clicking. The advantage: All employees know where each component has already been processed or even assembled.

- The backbone of HOMAG app communication: In the app world, "productionManager" acts as a central application in the background at many points and ensures that the right information appears at the right place in work preparation and the workshop.

- Interfaces to various software partners: Seamless data exchange with imos iX and other partners is fully automated and completely uncomplicated. The result is a continuous data flow from a single source.

- Clear Order Management: All employees in the office, on the shop floor or will have access to all orders in the plant

- Display of order progress in real time for easy tracking

- Archive your jobs in the digital job folder

- Digital Assistant for quick response

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

productionManager

The productionManager helps streamline work processes by providing a centralized platform for work preparation and production management. It enables users to have a clear overview of orders, monitor job progress, and manage tasks efficiently. The software offers features that enhance efficiency in the workshop. It provides tools for job scheduling, resource planning, and optimized job sequencing, allowing users to minimize setup times and increase productivity.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.