intelliDivide Cutting

intelliDivide Cutting

Share

Collapsible content

Production Description

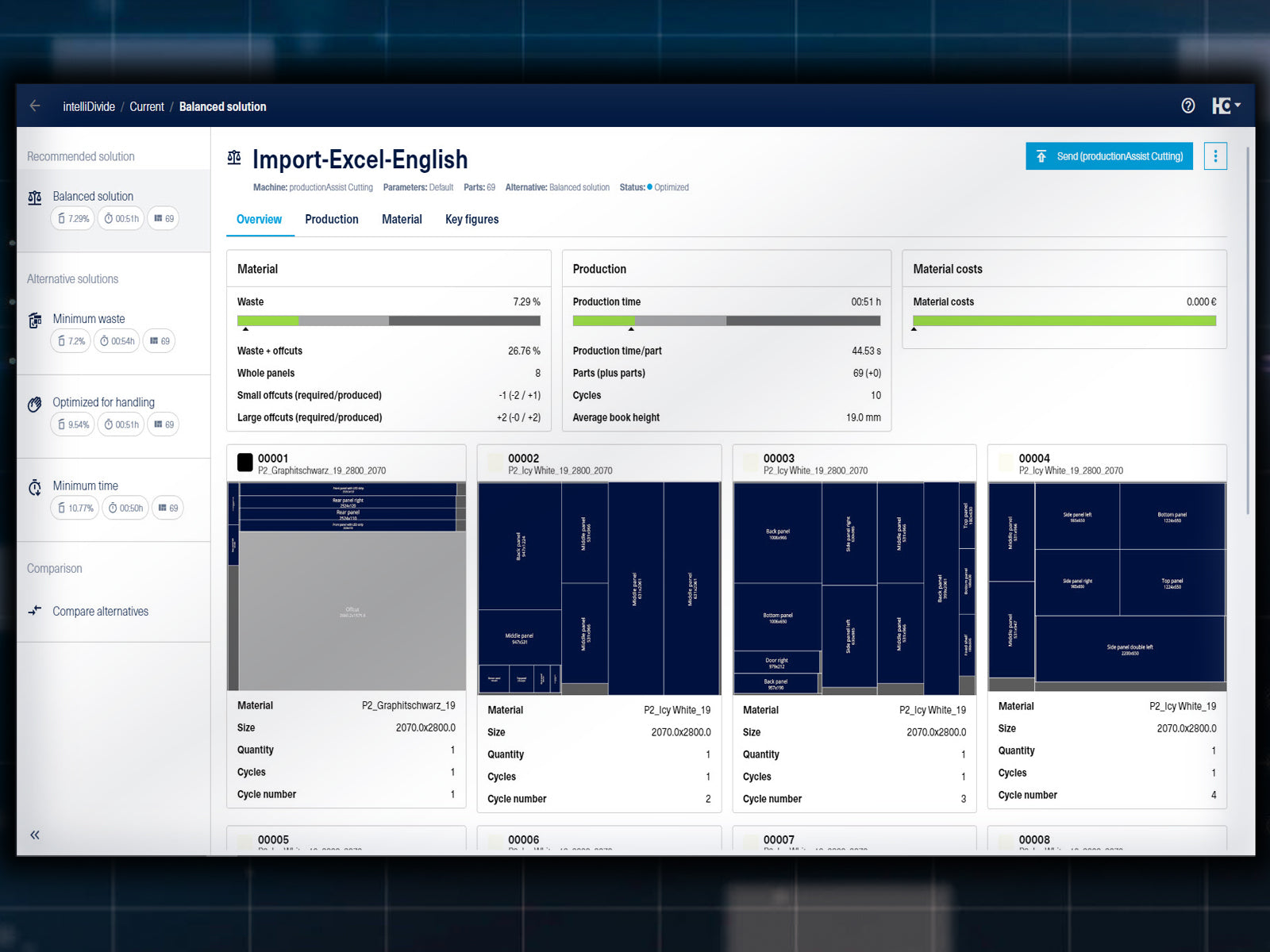

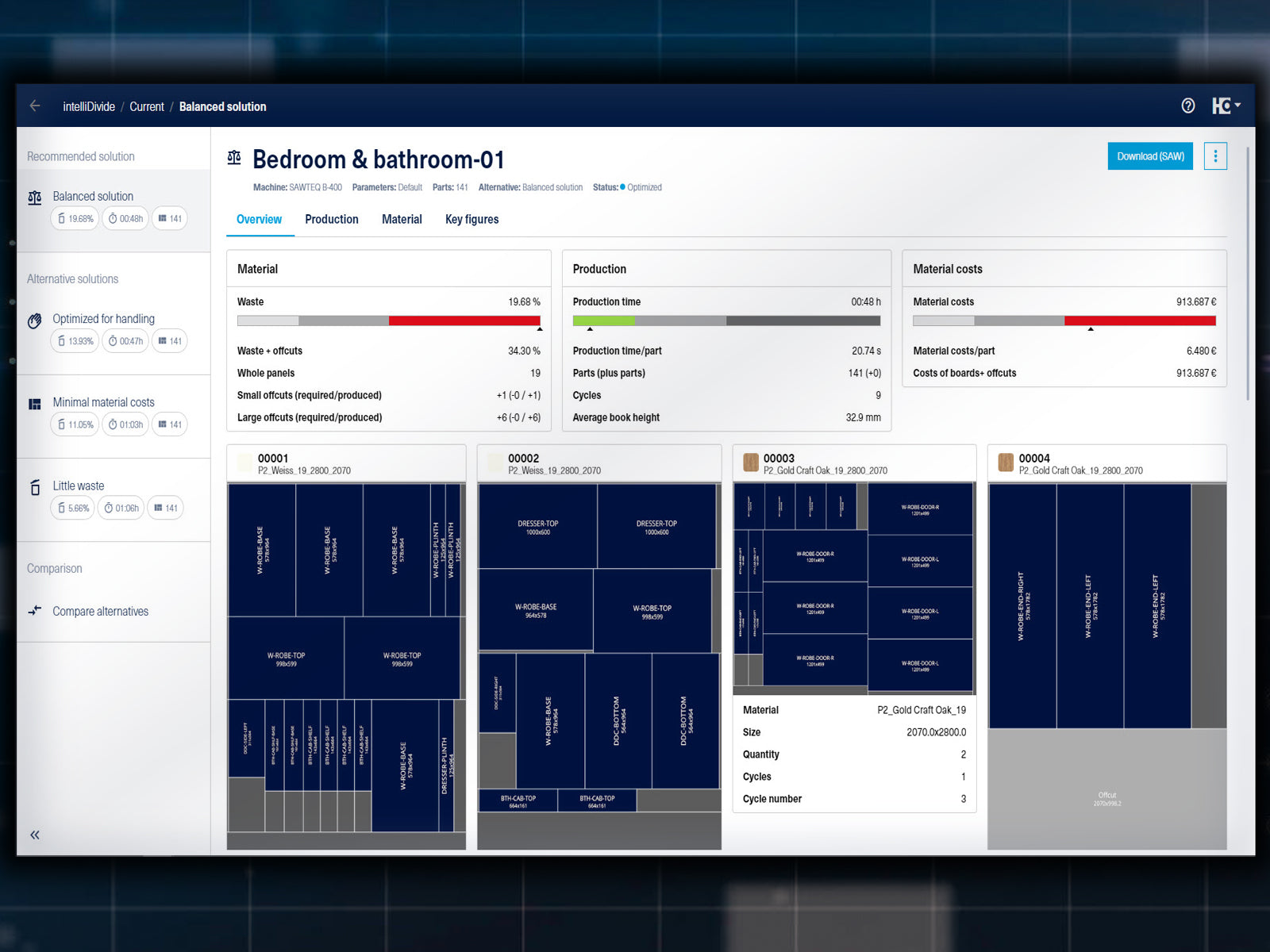

Simply upload the parts list. Done! intelliDivide gives you a choice of optimized cutting patterns in an instant. Depending on requirements, results can be based on reducing waste or focus on the shortest production time or the simplest handling. And all without having to invest in software and computing power – directly from the tapio cloud.

Highlights

Benefits

- Compatible with all saws: Your tapio-ready saw from HOMAG is automatically identified. There are configuration options for all other saw types.

- Zero capital investment costs, zero hardware costs: intelliDivide is Software as a Service. You only pay for the actual use without having to invest in on-premise software, updates or computers,

- Greatly reduced personnel costs and time involved. Multiple alternatives are always calculated for you to choose from. The results are immediately ready for the machine, requiring no adjustments. No manual post-processing required.

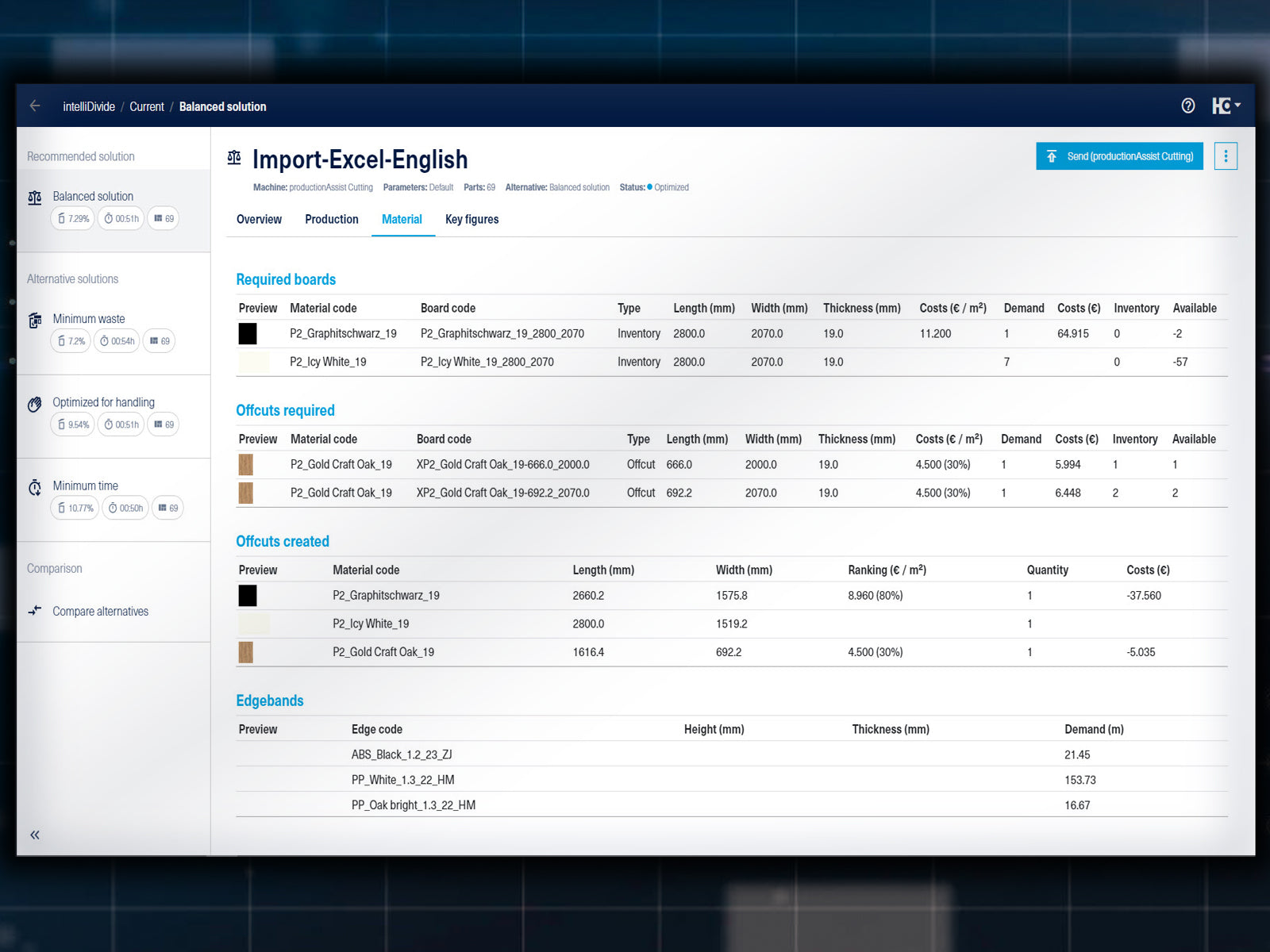

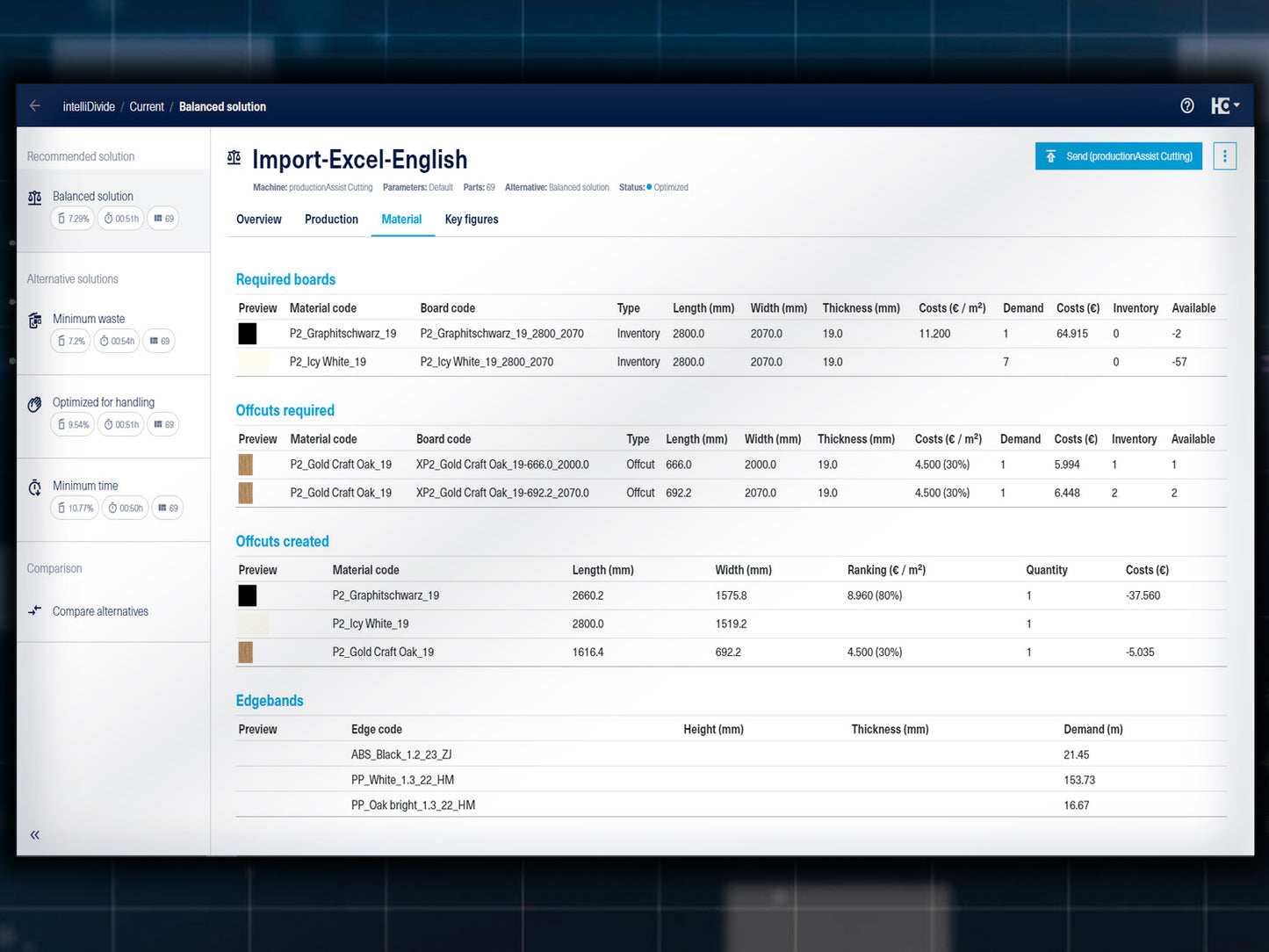

- Material management included: The materialManager for central management of material types and board sizes for the optimization is included.

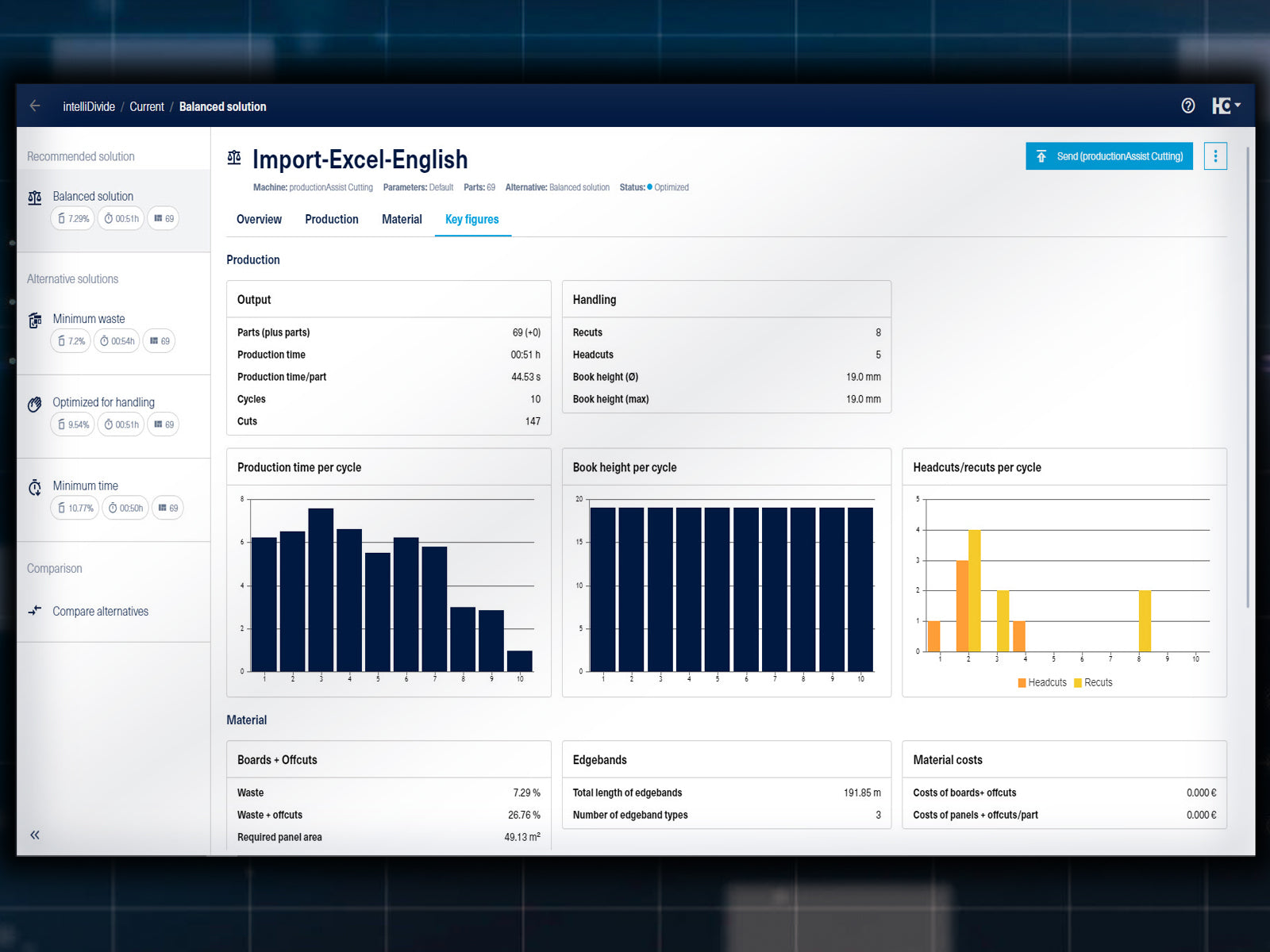

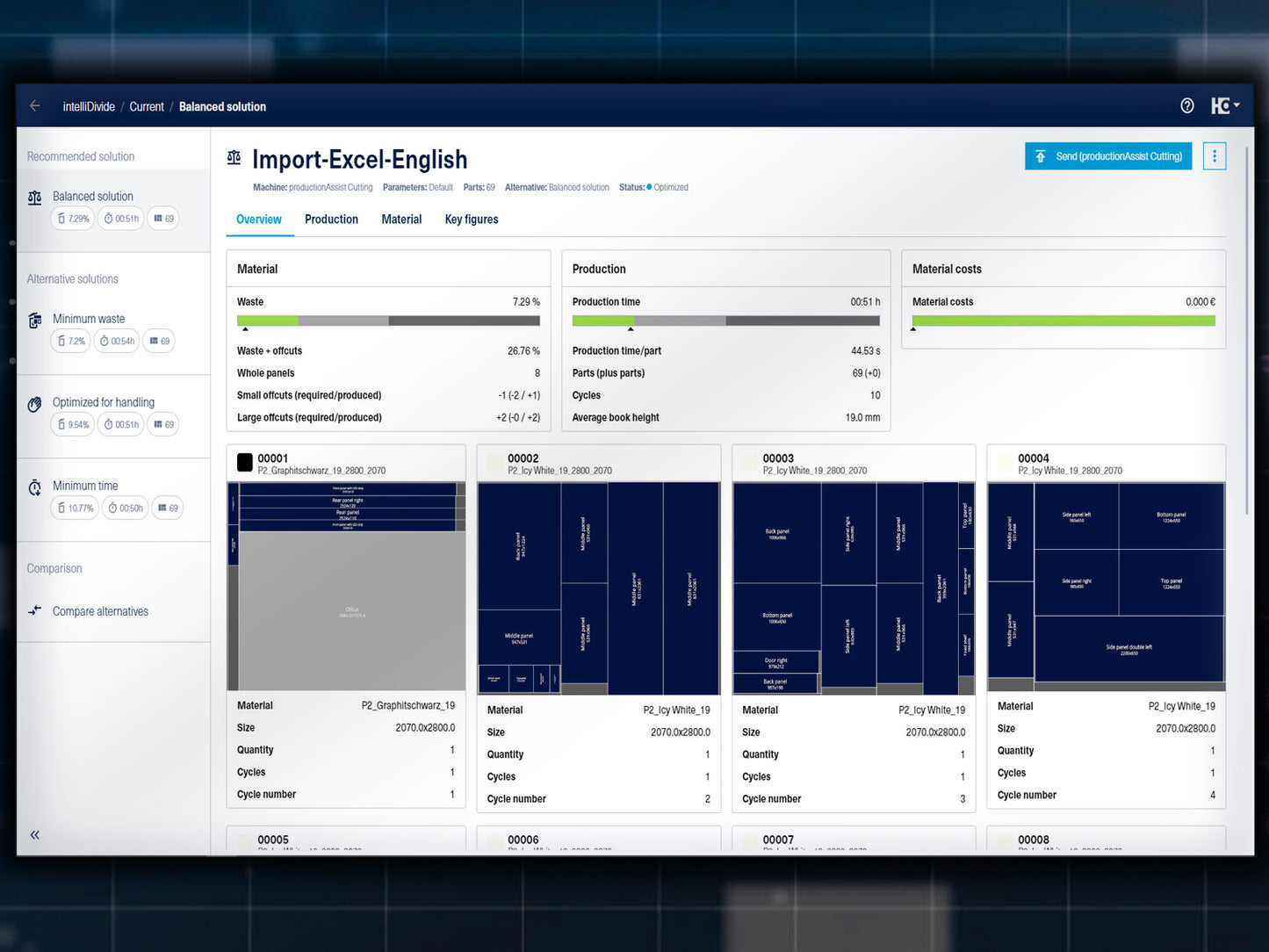

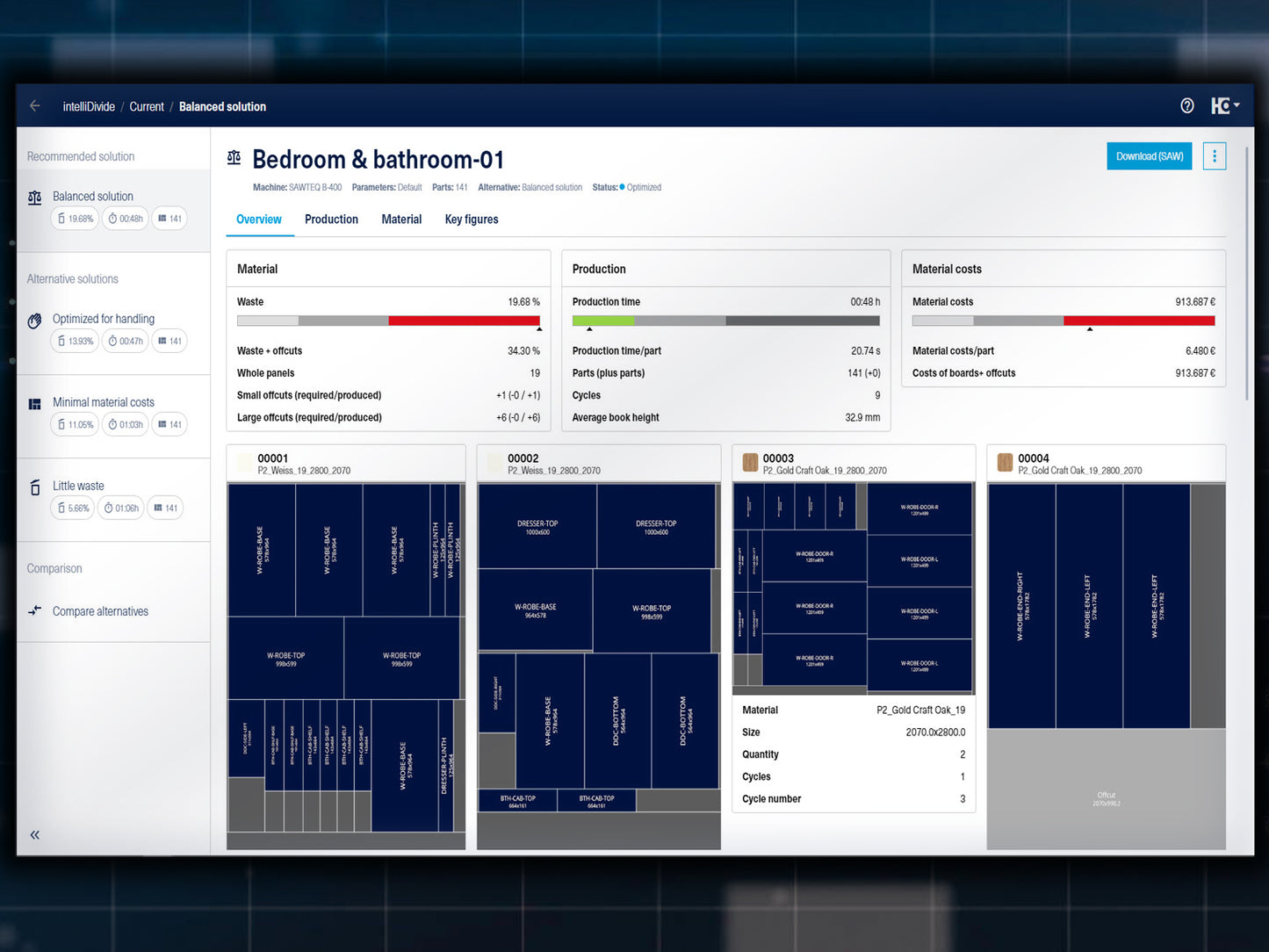

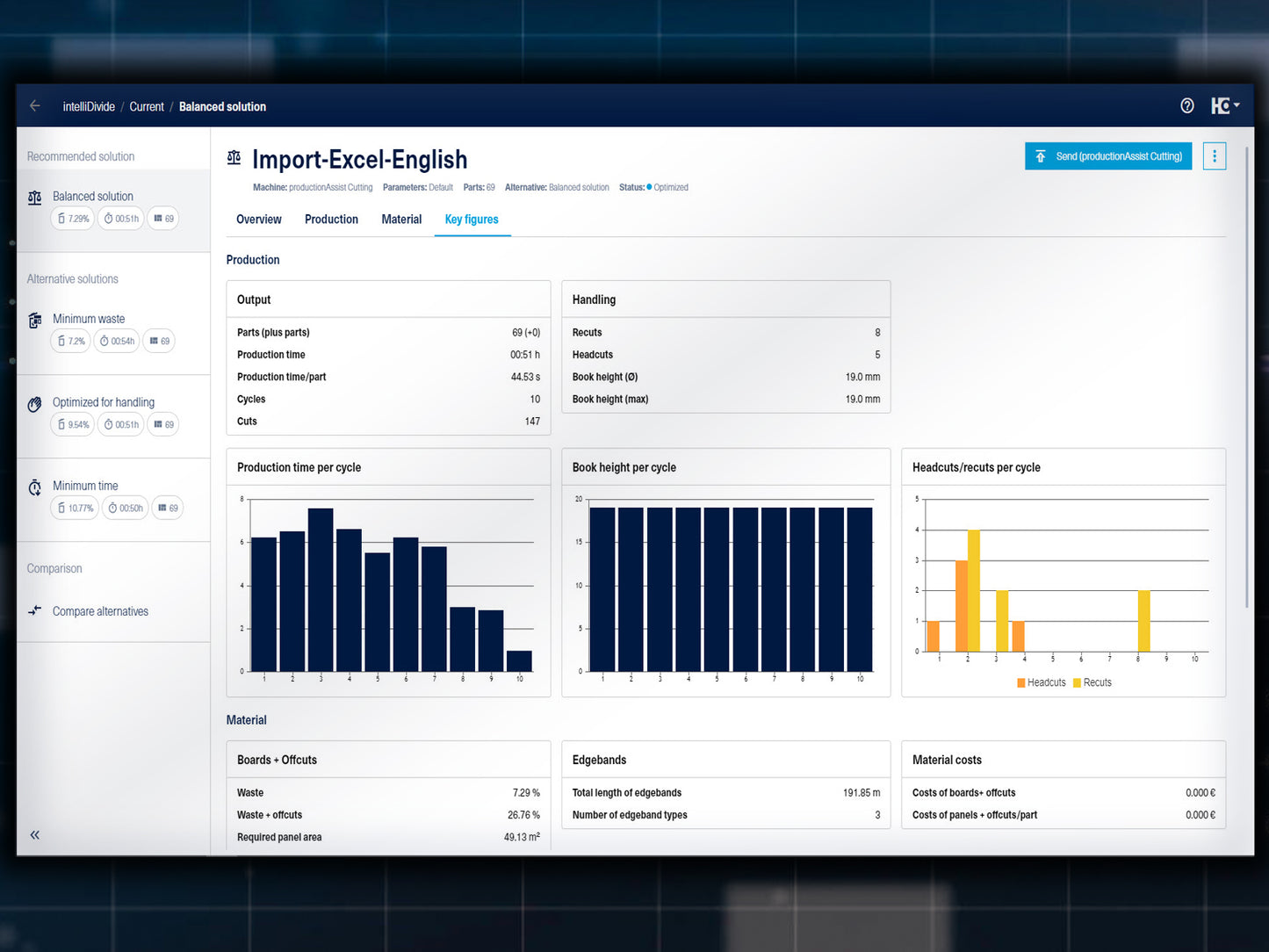

- Detailed information with all important figures

- Job Summary- Simple & Comprehensive

- Selection & comparison of alternatives - Choose your favorite

- Patter Preview- as detailed as required

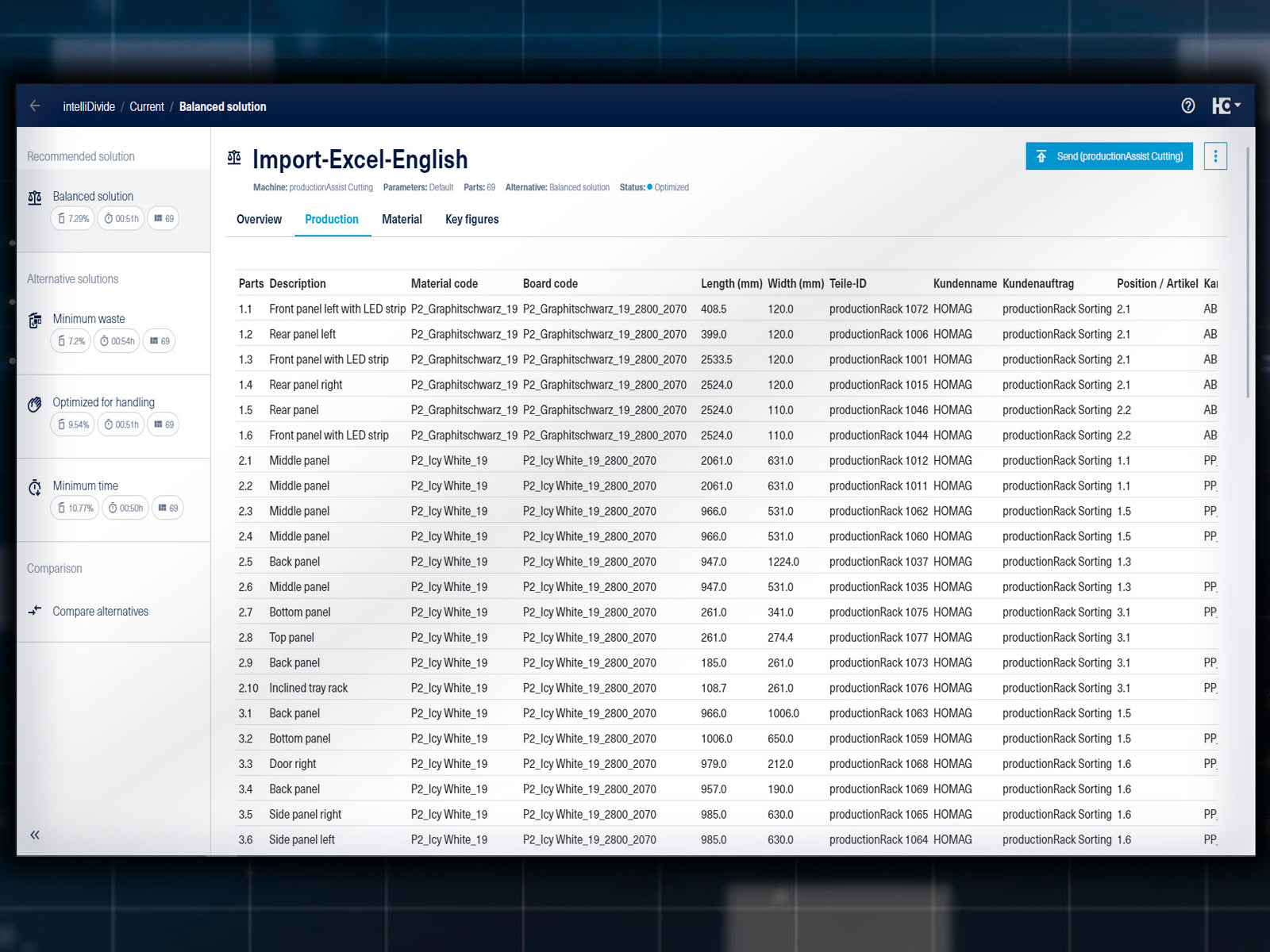

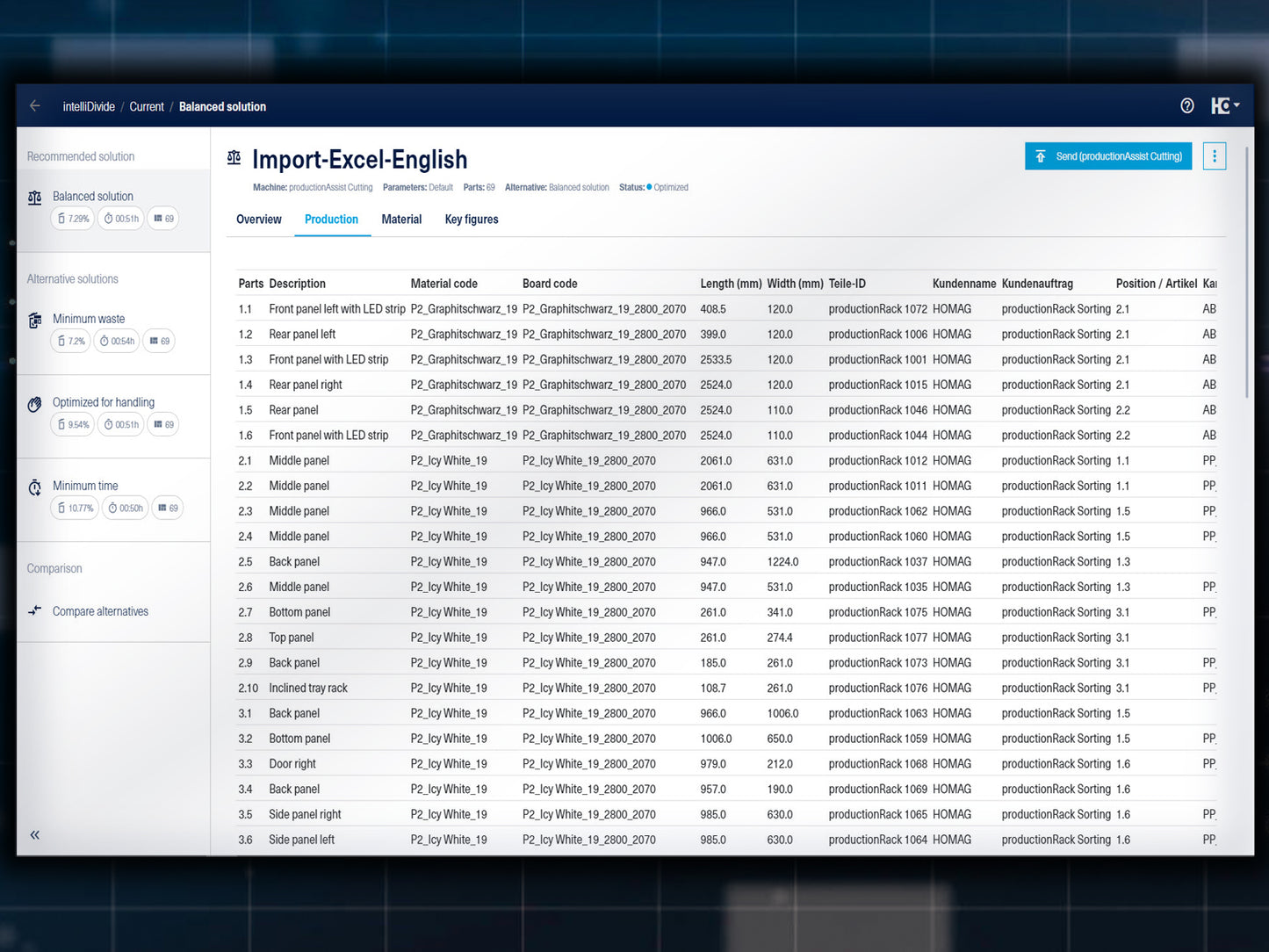

- Provides an overview of all parts

Simple and Intuitive Controls

Sanding Heads

Technical Details

- intelliDivide Cutting is a browser application for use on a PC or laptop

- Internet access (DSL, UMTS, LTE): min. 5 Mbit/recommended: 50 Mbit

- Browser application: for use on a PC or laptop, we recommend using Microsoft Edge", "Google Chrome" or "Firefox" as a browser

- Log in via tapio login (tapio registration required)

Features

- Direct transfer of the selected result to tapio-ready machines

- Calculation of important key figures such as material costs, parts/min. or average stacking heights in the cutting process

- Definition of offcuts by minimum and maximum dimensions

- Automatic transfer of data from HOMAG production Manager

- Direct access to board data from the HOMAG materialManager

- Can be combined with intelliDivide Nesting - two technologies, one system!

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

intelliDivide Cutting

intelliDivide Cutting uses advanced algorithms to optimize cutting patterns, resulting in efficient material usage and minimized waste. The software offers various cutting pattern options based on different criteria, such as waste reduction or production time optimization. Users can choose the most suitable option based on their specific requirements, allowing for greater flexibility in the production process.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.