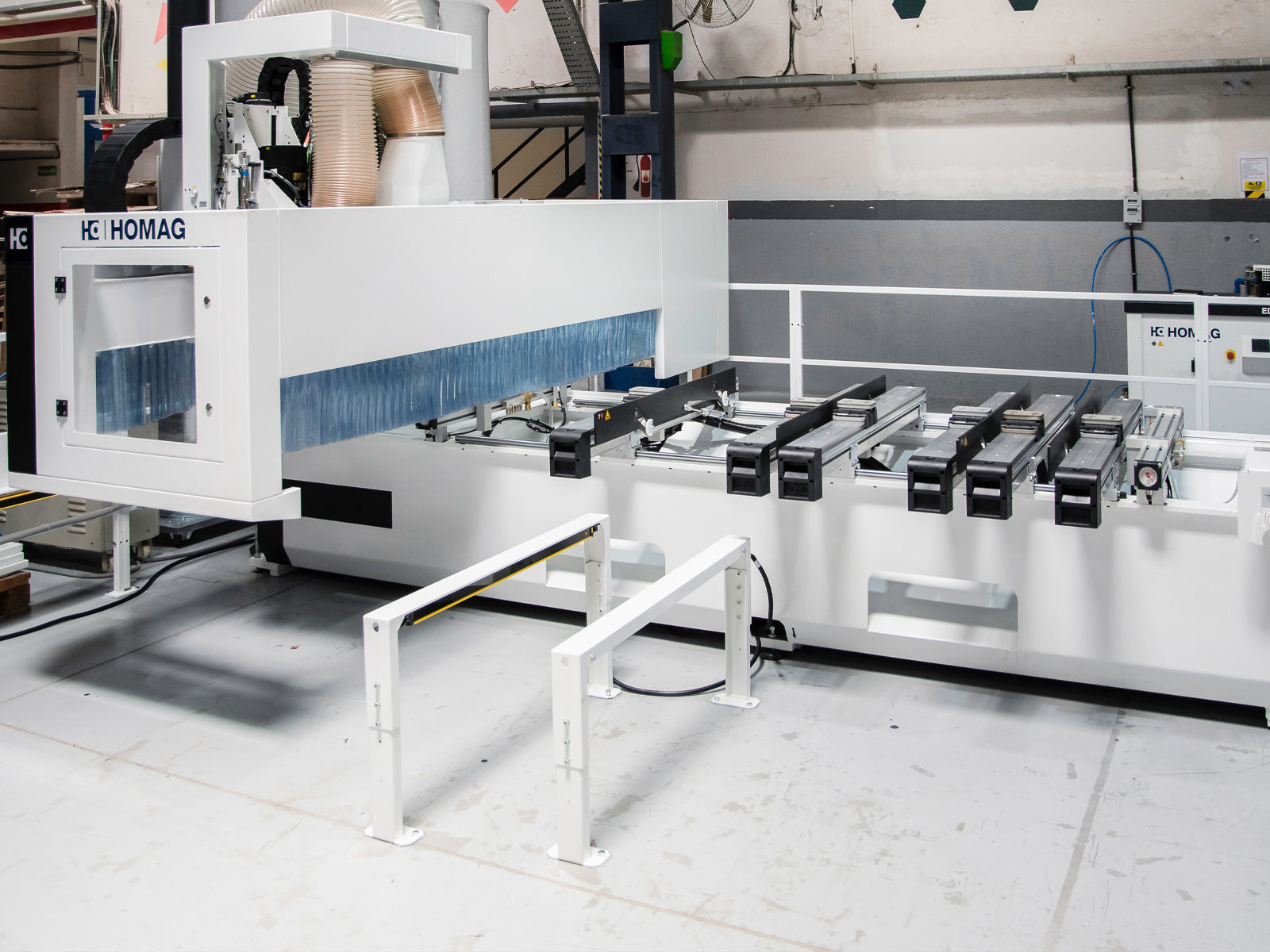

CENTATEQ P-100

CENTATEQ P-100

Share

Collapsible content

Production Description

Due to their compactness and productivity, the machines of this series are ideal for small and medium-sized enterprises, in particular, specializing in the production of cabinet furniture. The machine concept is based on compact technology, smaller footprint and machine-oriented control.

Highlights

- Versatile processing center with 4- field loading feature

- Routing up to 1600 mm in Y direction and a software optimized working field

- Variable processing speed and configurable drill blocks with grooving saw

- Quick and effortless positioning of the vacuum cups

- Automatic spindle clamping system for precise depth

- Integrated access to woodWOP with a massive collection of CNC programs

- Flexible and customizable for multiple configurations

Benefits

Simple and Intuitive Controls

Sanding Heads

Technical Details

| Specifications | Classic | Professional | ||||

| X | Y | Z | X | Y | Z | |

| Working field (X-Y-Z) [mm] | 2450 | 1600 | 100 | 3250 | 1600 | 100 |

| Routing (Ø = 25mm) (X-Y-Z) [mm] | 2450 | 1600 | 100 | 3250 | 1600 | 100 |

| Drilling [mm] | 2450 | 1355 | 70 | 3250 | 1355 | 70 |

| Vector Speed [m/min]. | 65 | 50 | 20 | 65 | 50 | 20 |

| Electrical connection | Voltage 400 V | 50 Hz | 3 Phases | |||||

| Compressed air connection [inch] | R ½ | |||||

| Compressed air required [bar] | 7 | |||||

| Dust extraction port [mm] | Ø 200 | |||||

| Dust extraction volume [m³/h] | min. 3170 | |||||

| Total machine weight [kg] | approx. 2500 | |||||

| Electrical power – total connection load [kW] | 17,5 | |||||

| Switch cabinet L – W – H [mm] | 1560 – 480 – 745 | |||||

Some parameters of the work piece depend on the tools used. More detailed technical data can be provided in the relevant brochure.

Features

- Spindle Lock Feature: The Spindle Lock Feature feature allows for consistently accurate drilling depths, which helps maintain product quality without needing to make frequent manual adjustments.

- 4-Fold Bearing Design: The drilling spindle uses a bearing design that efficiently handles different types of loads (axial and radial), resulting in smoother operations and better machine efficiency.

- Pneumatic Advance and Return Mechanisms: These mechanisms are part of the Homag Drilling Block Technology which aim to increase the longevity of the drill block components, reducing the need for replacements and maintenance.

- High-Precision Polygonal Guide: This component ensures that the drilling tasks are carried out with a high degree of accuracy and reliability, contributing to the overall precision of the CNC process.

- Variable Speed Control (1500 to 7500 rpm): The machine offers a range of speed settings, allowing it to work effectively with different materials and project requirements, adding to the machine's versatility in production capabilities.

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

CENTATEQ P-100

The CENTATEQ P-100 is a highly efficient CNC Processing center. Its automatic tool changer and integrated tool management system optimizing CNC operations and maximizing output. With a strong focus on precision and durability, this machine is built to deliver top-notch results consistently. With its compact design and efficient features, the CENTATEQ P-100 is the perfect choice for small to medium-sized cabinet furniture workshops. It provides reliability, productivity, and operator-friendly functionality while minimizing space requirements.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.