Nesting Production Set

Nesting Production Set

Share

Collapsible content

Production Description

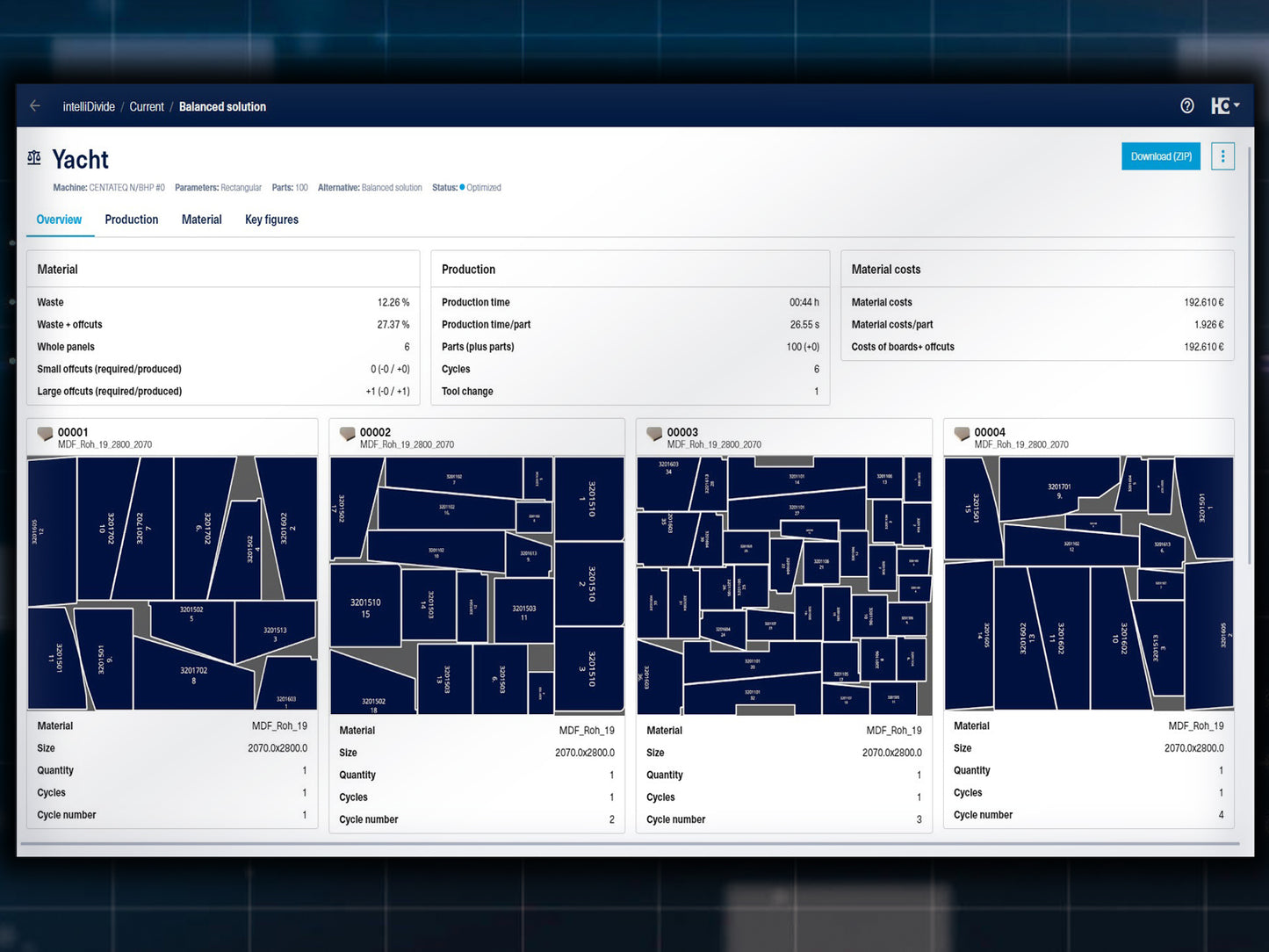

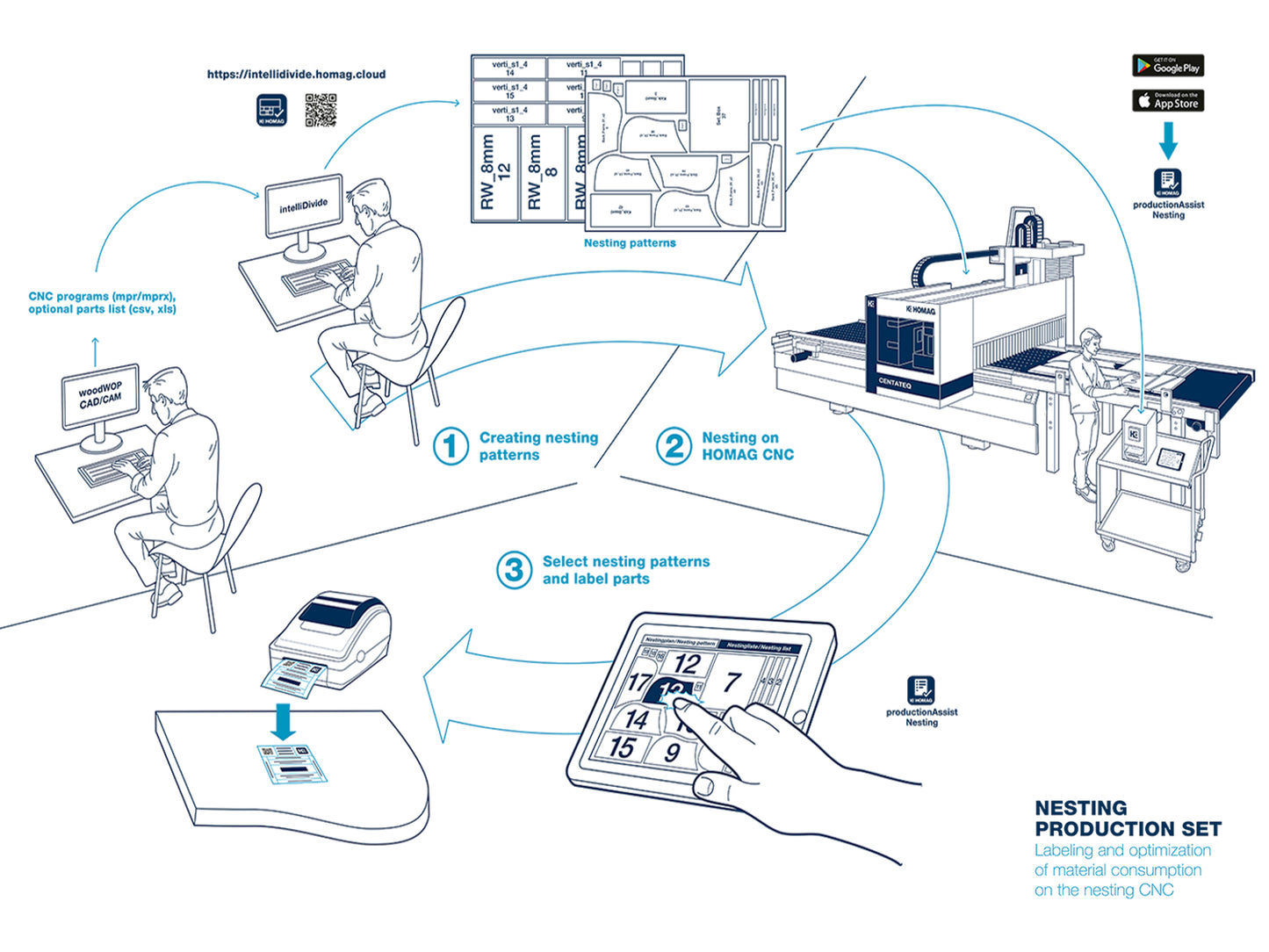

Our nesting assistant supports you in the automatic calculation of your nesting patterns.The optimization software places the individual components in the nest as close together as possible. This allows you to noticeably reduce material consumption and save costs. At the same time, you print an individual label for each nested part and generate the basis for consistent processing data in your carpentry already at your nesting machine. The Nesting Production Set is the ideal entry-level solution for labeling your parts and is perfectly suited for retrofitting label printing to HOMAG CNC nesting machines.

Highlights

Benefits

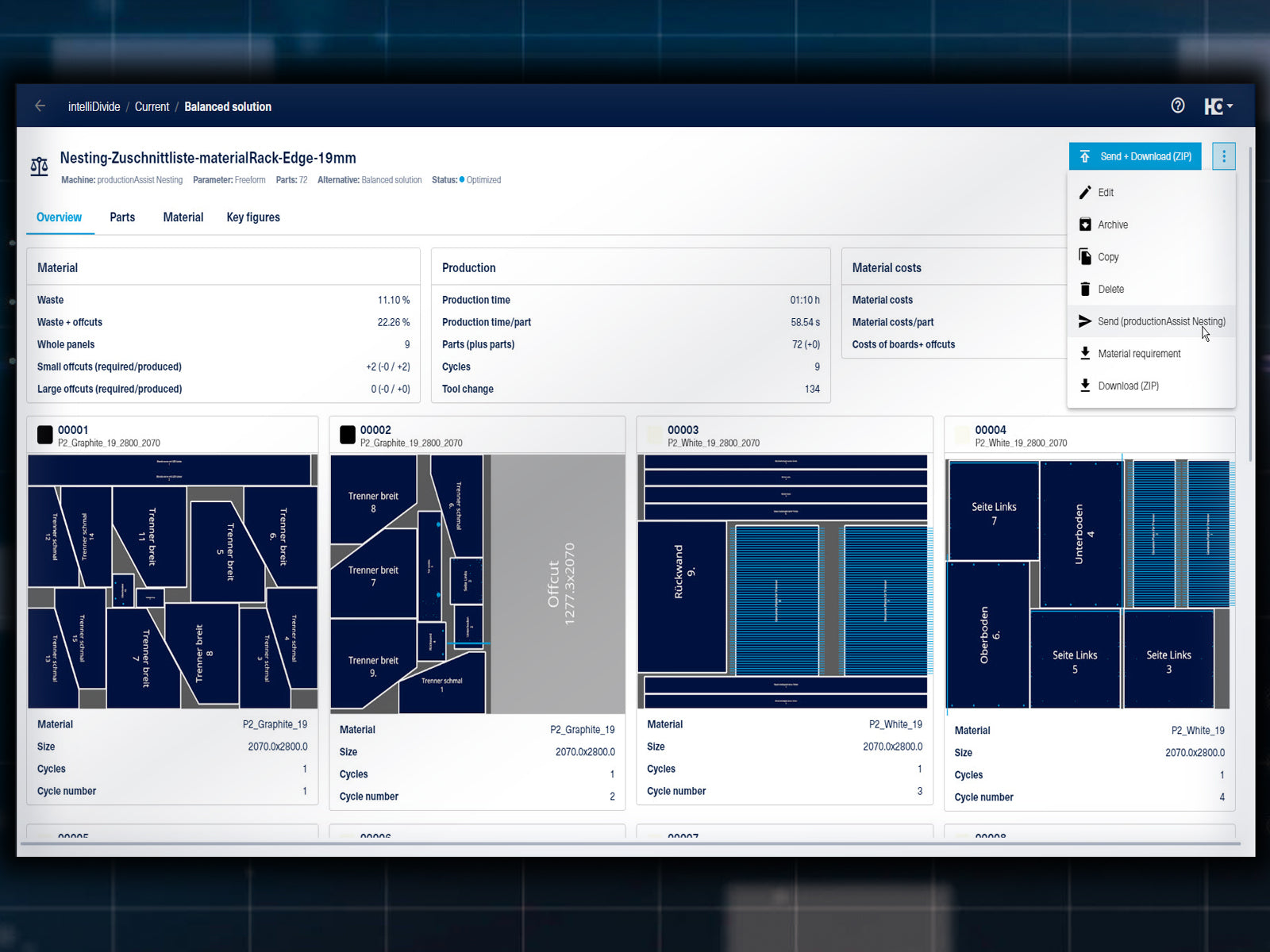

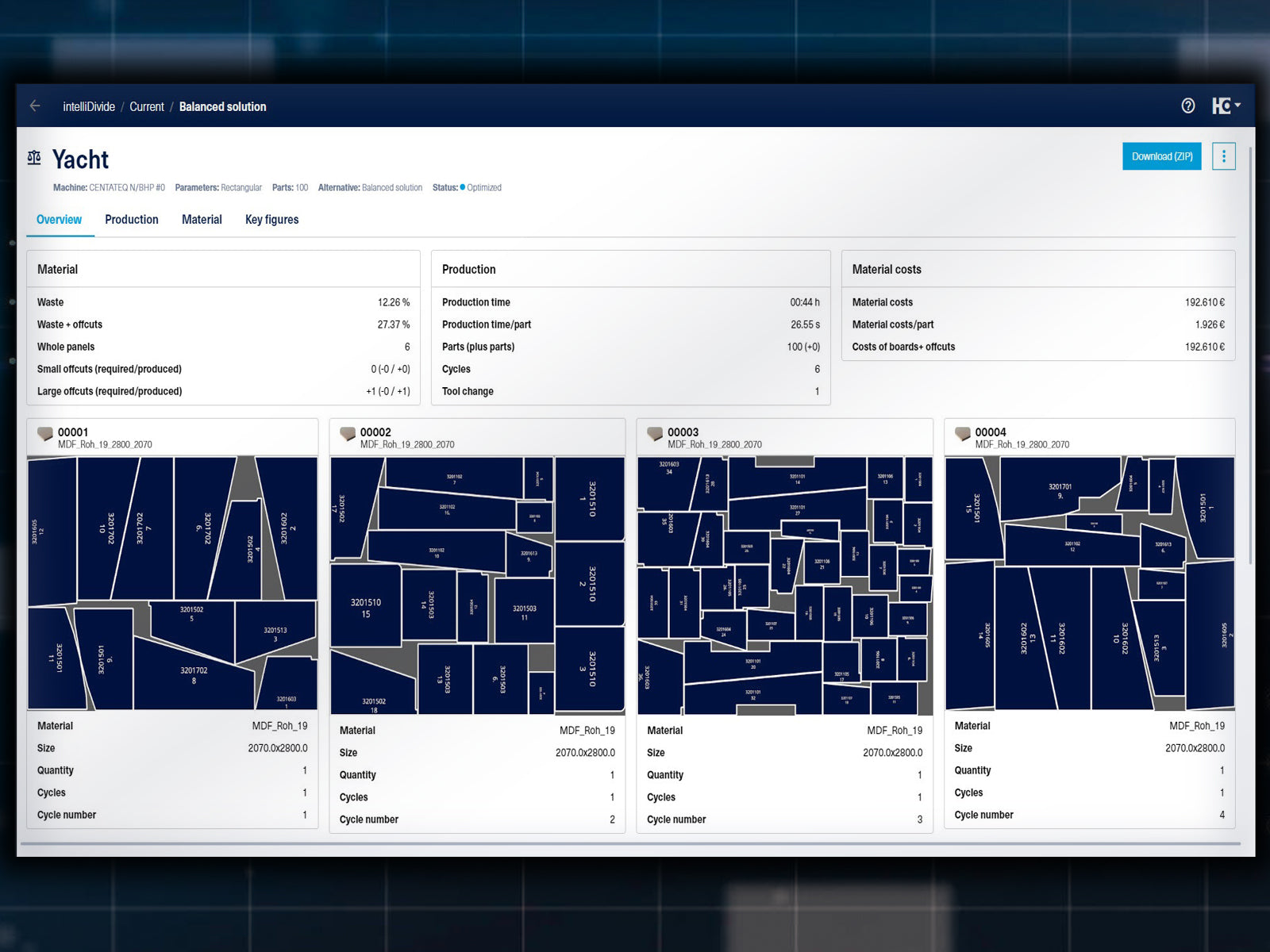

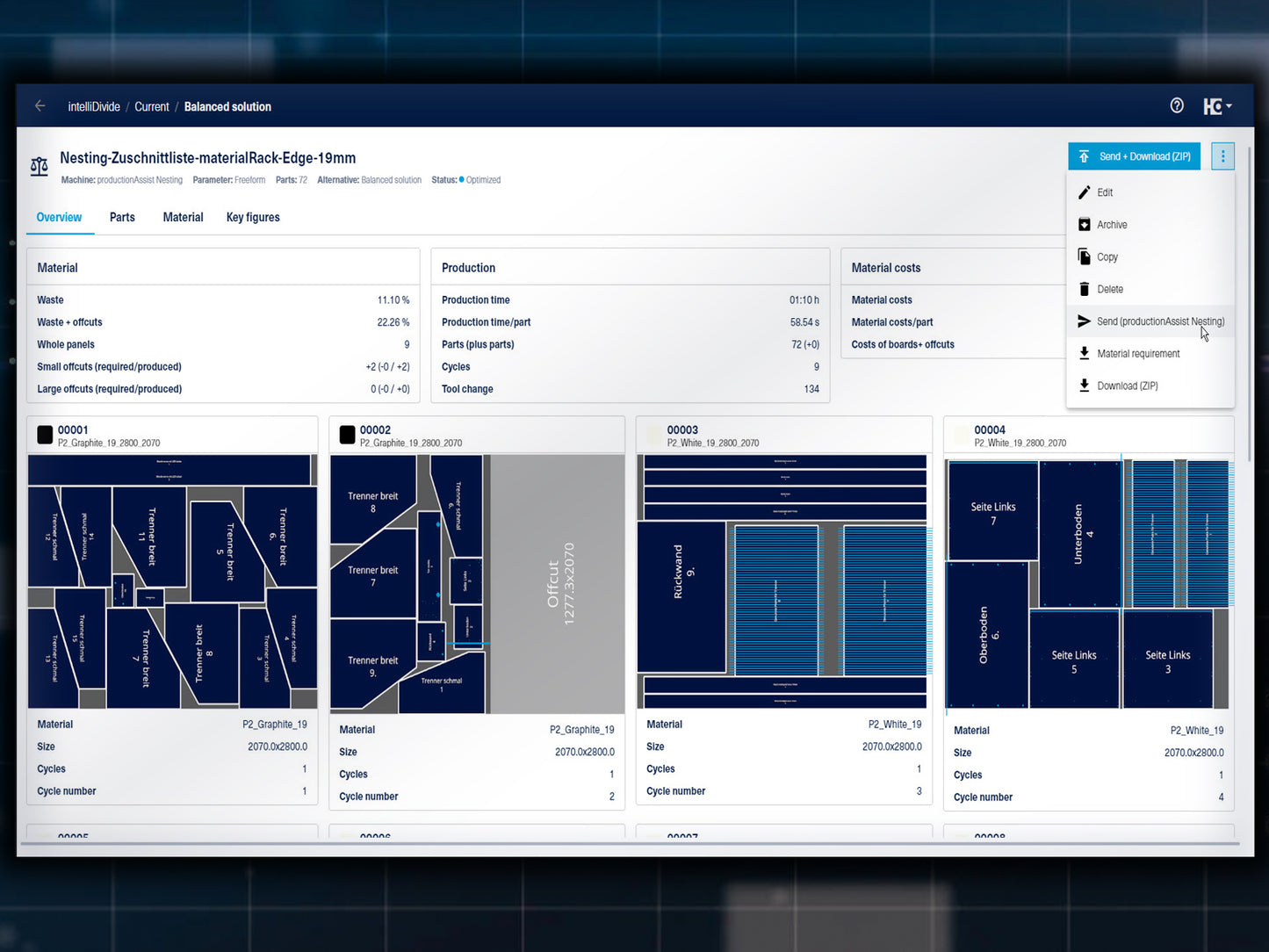

- Save material - You simply optimize your nesting patterns with the "intelliDivide Nesting" optimization software in job preparation. With just one click, you can load the automatically calculated nesting patterns onto the machine and process them

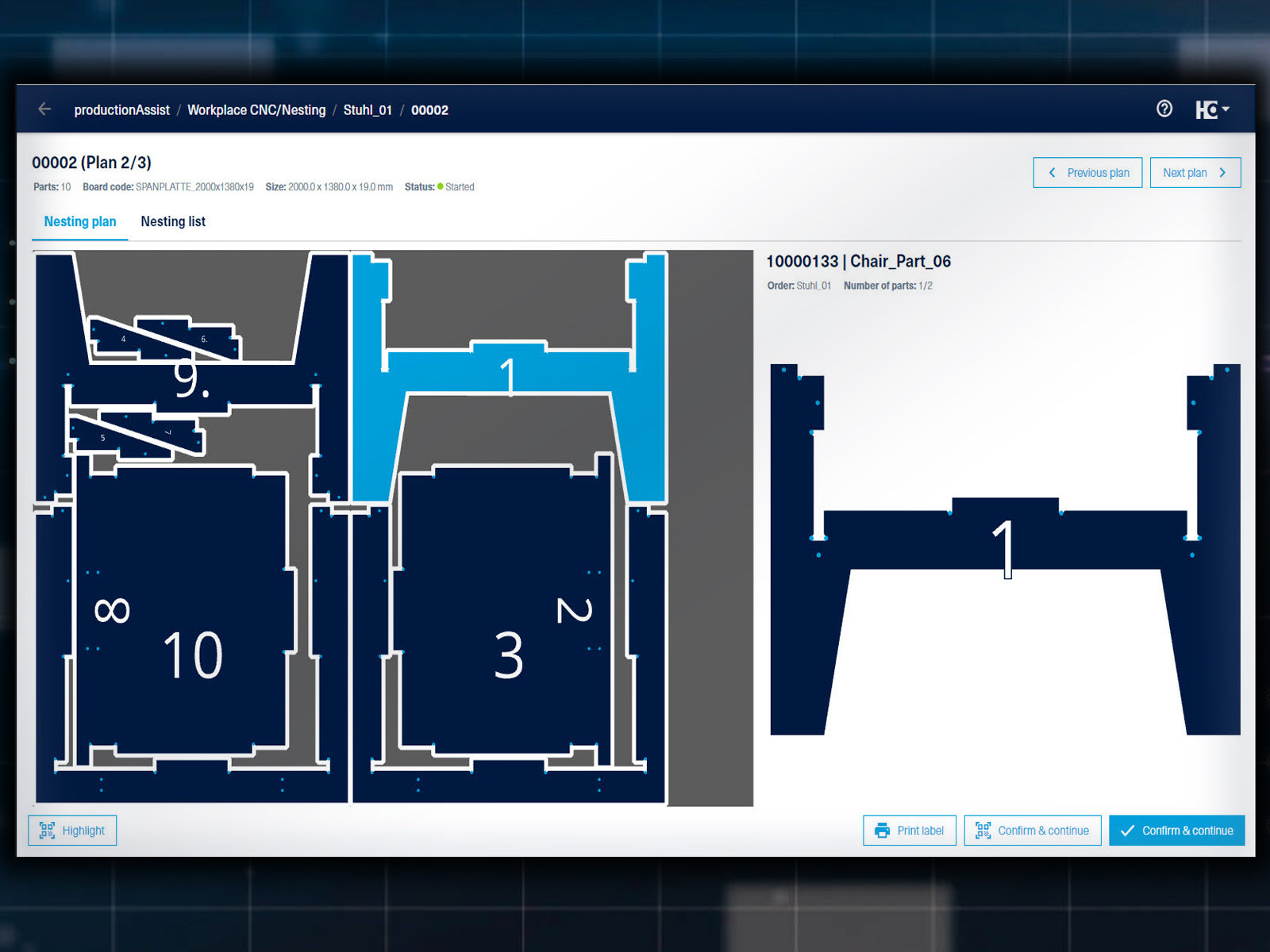

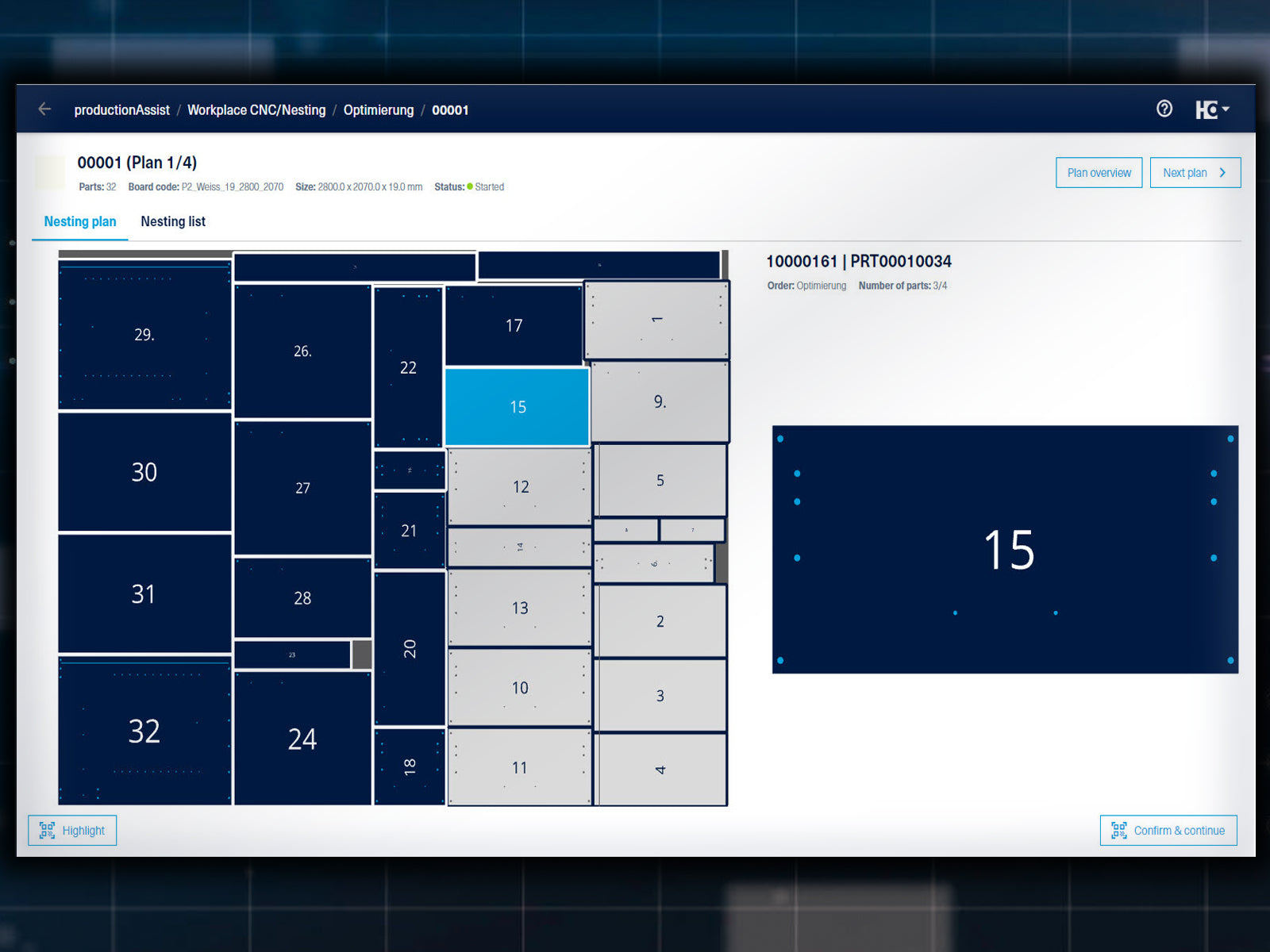

there. In this way, you significantly reduce material consumption. - Consistent machining data - With the app on the tablet in the workshop, you print a label for each nested part. This means that each workpiece has all the relevant information right from the start. This includes, for example, the job name, information on the part and edging, or a barcode or QR code for further processing.

- Flexible retrofitting - Easy to use in conjunction with all HOMAG Nesting machines, regardless of year of manufacture and series.

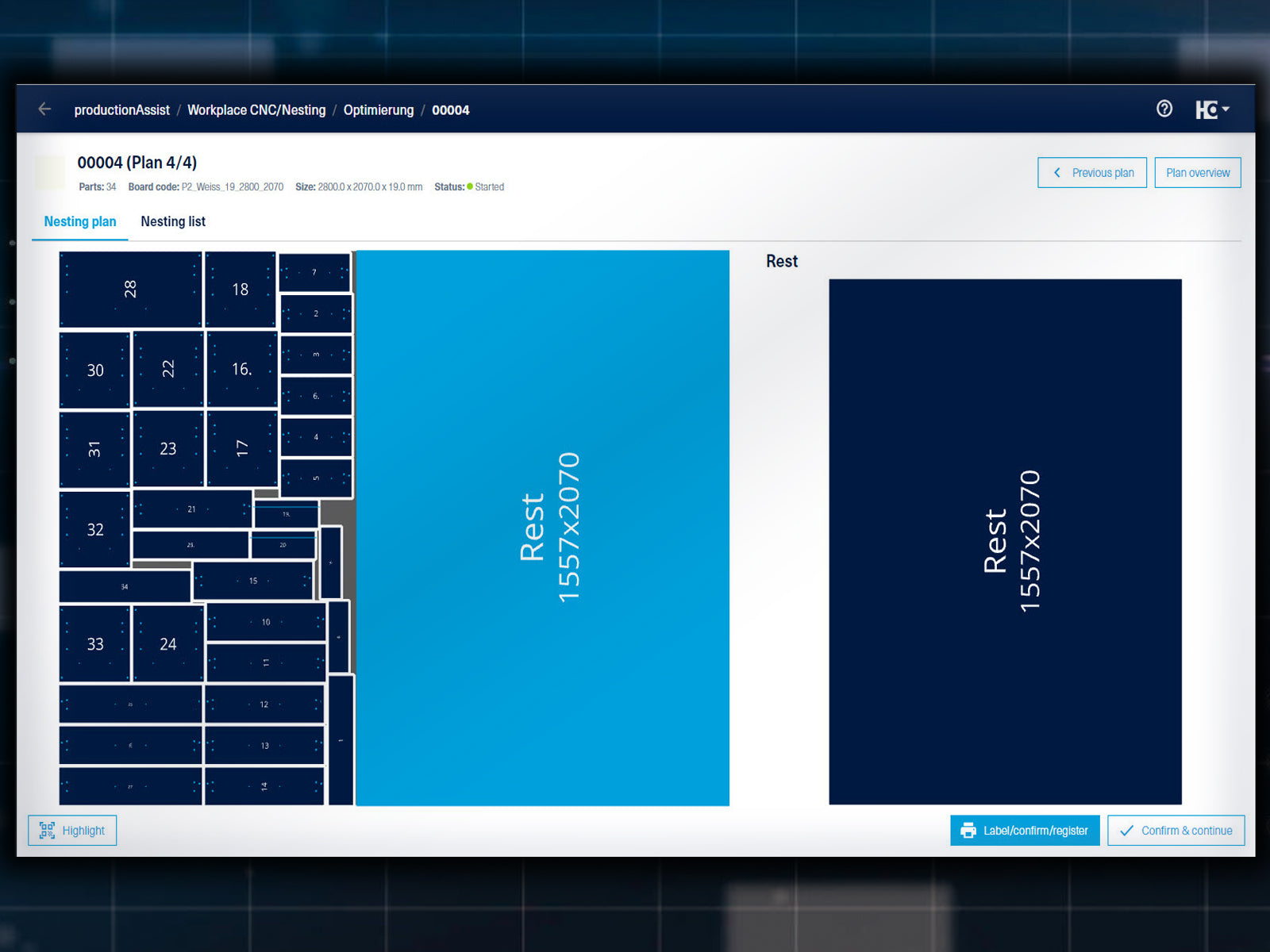

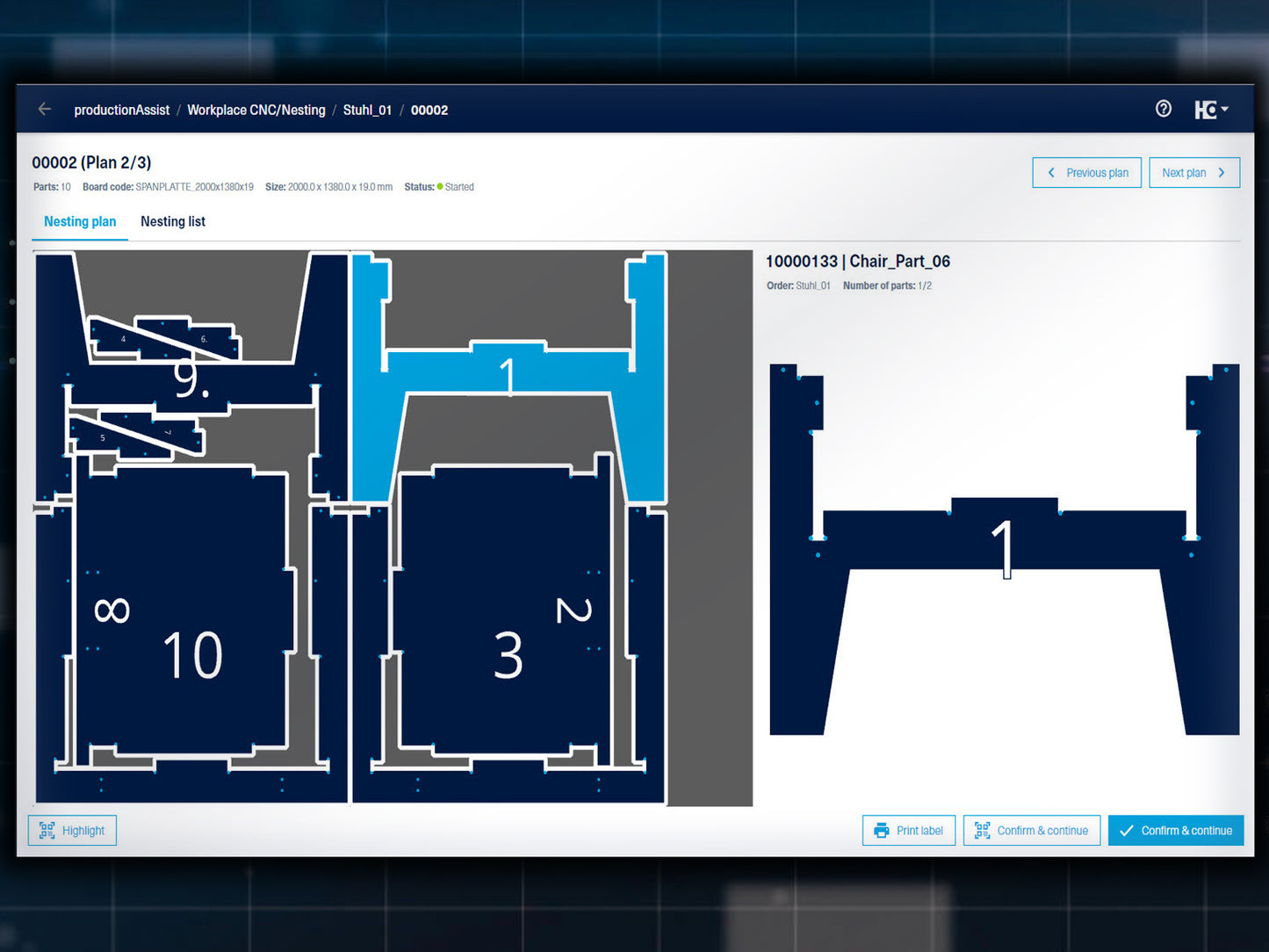

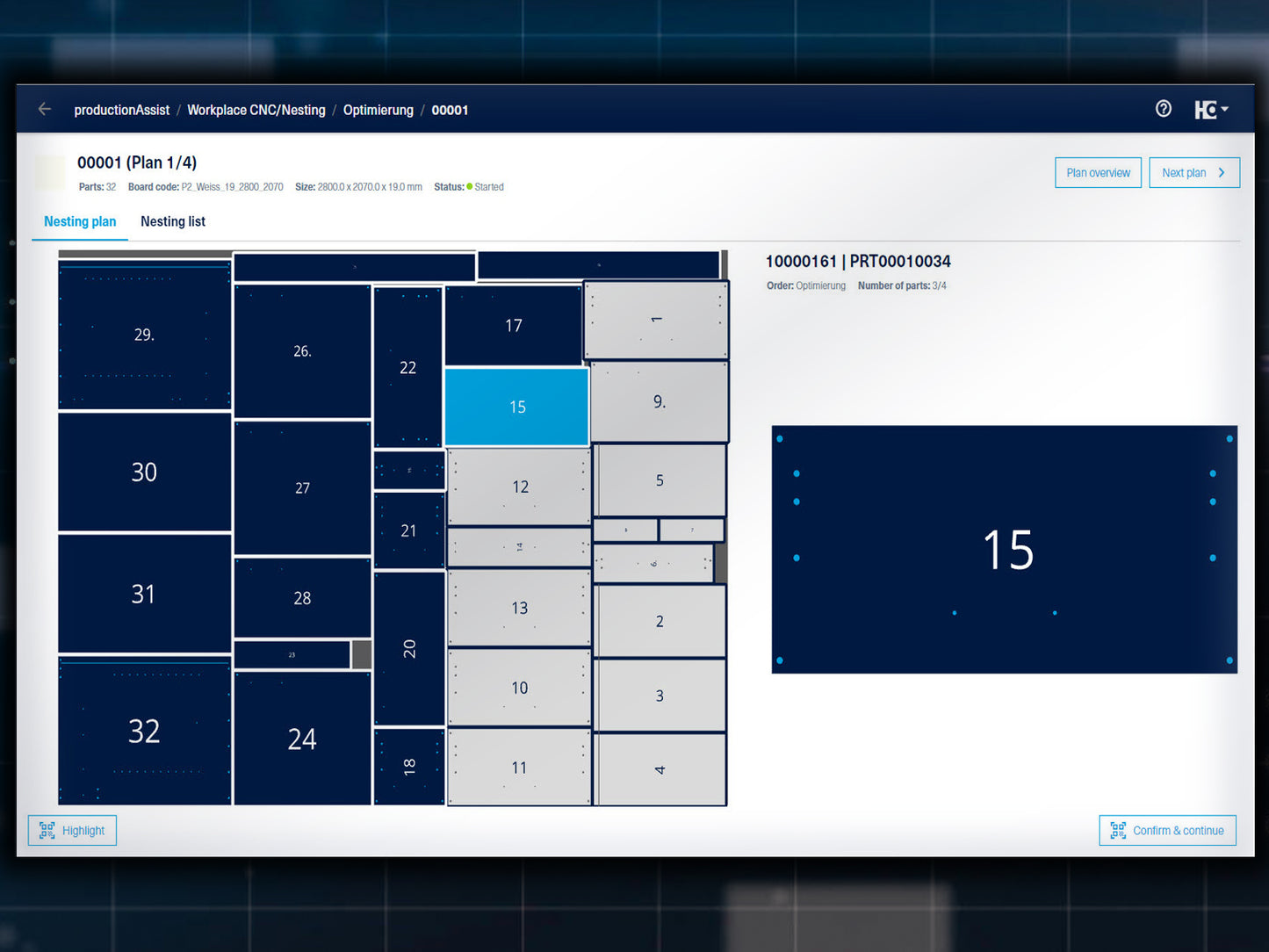

- Calculated nesting plan in intelliDivide nesting.

- Sending nesting patterns to the prodcutionAssist Nesting.

- Selection of a component & printing of the corresponding label.

- Overview of parts that have been labeled

- Printing of all labels at once.

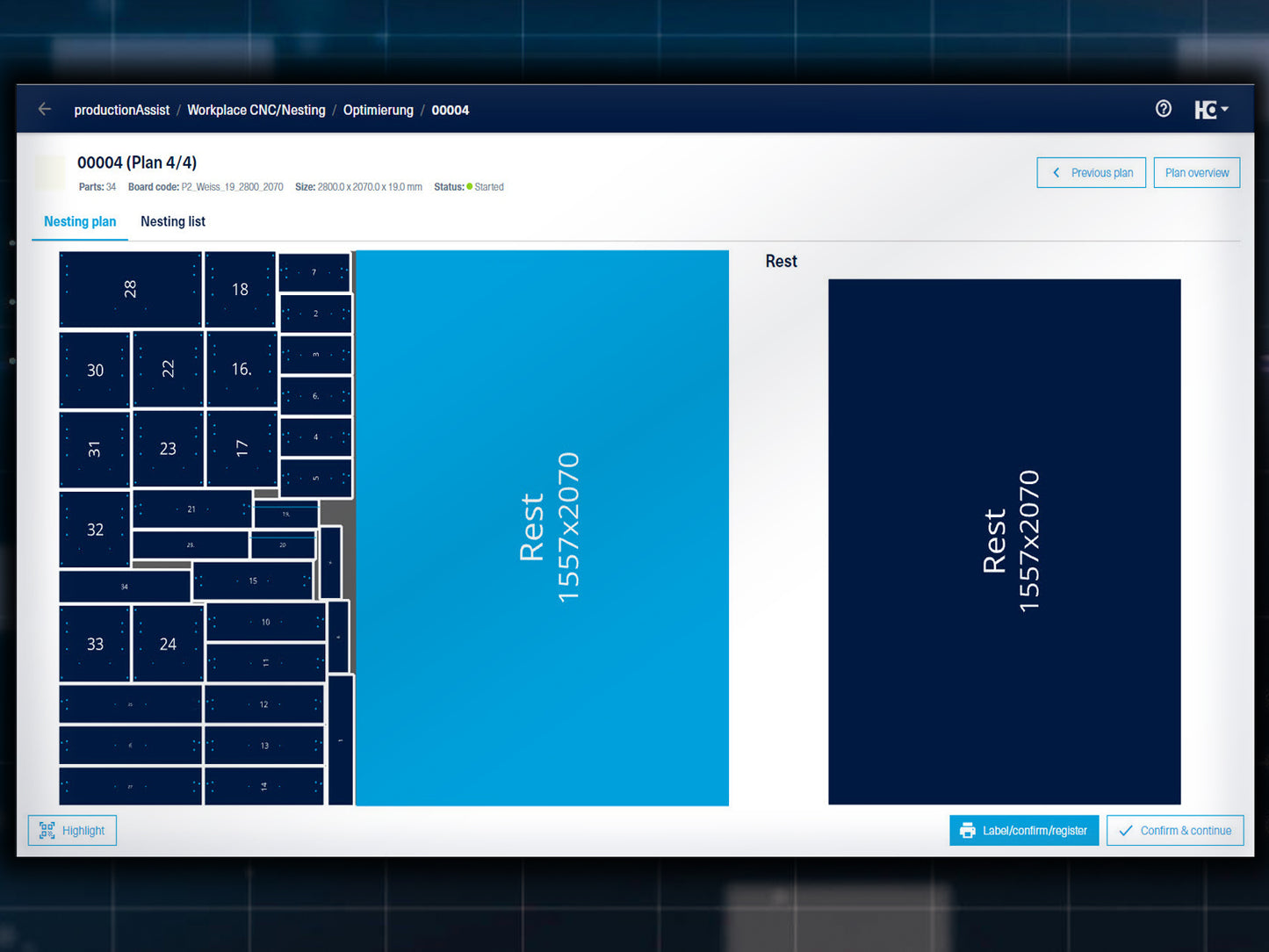

- Selection of an offcut piece & printing of the corresponding label.

- Selection & label printing for freeform parts.

Simple and Intuitive Controls

Sanding Heads

Technical Details

Features

What does the "Nesting Production Set" consist of?

- Four apps: “intelliDivide Nesting” (optimization software for nesting plans), "productionAssist Nesting" (assistant for labeling nested parts), materialManager (cent al material management) & materialAssist Boards (management of boards and offcuts at the workplace)

- Label printer including two rolls of labels

- HOMAG CUBE (intelligent control box for connecting the printer to the Internet and the apps)

- Installation Guide

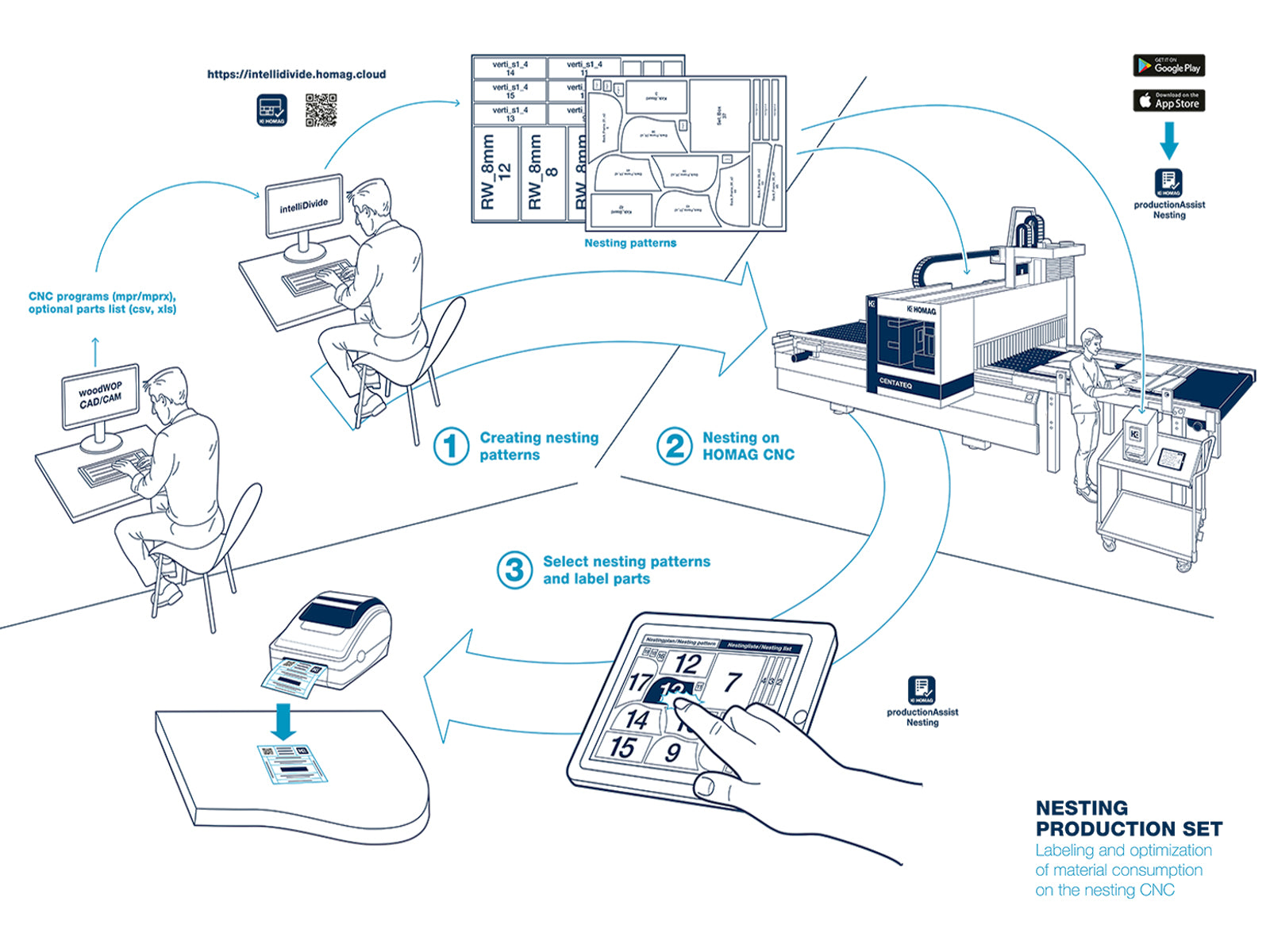

The workflow in the workshop:

- You start the optimization of an order with the "intelliDivide Nesting" software in the work preparation department in the office. Then you load the automatically calculated nesting patterns onto the machine. At the same time, you send the patterns to the "productionAssist Nesting" app on the tablet in your workshop.

- There, you start nesting processing on your HOMAG CNC.

- Once the nesting program has been processed, you select the nesting pattern on your tablet.

- Simply click to print out the labels individually for each part or the labels for the entire plan using the label printer.

- This means that each part is clearly identifiable and carries all the important information with it - such as the job name, information on the component and edging, or a barcode or QR code for further processing.

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

Nesting Production Set

With the Nesting Production Set, users have access to real-time data regarding material usage, nesting optimization, and production progress. This information allows for better decision-making, planning, and resource allocation, leading to improved overall production control. The Nesting Production Set can be easily retrofitted to existing HOMAG CNC machines for label printing functionality.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.