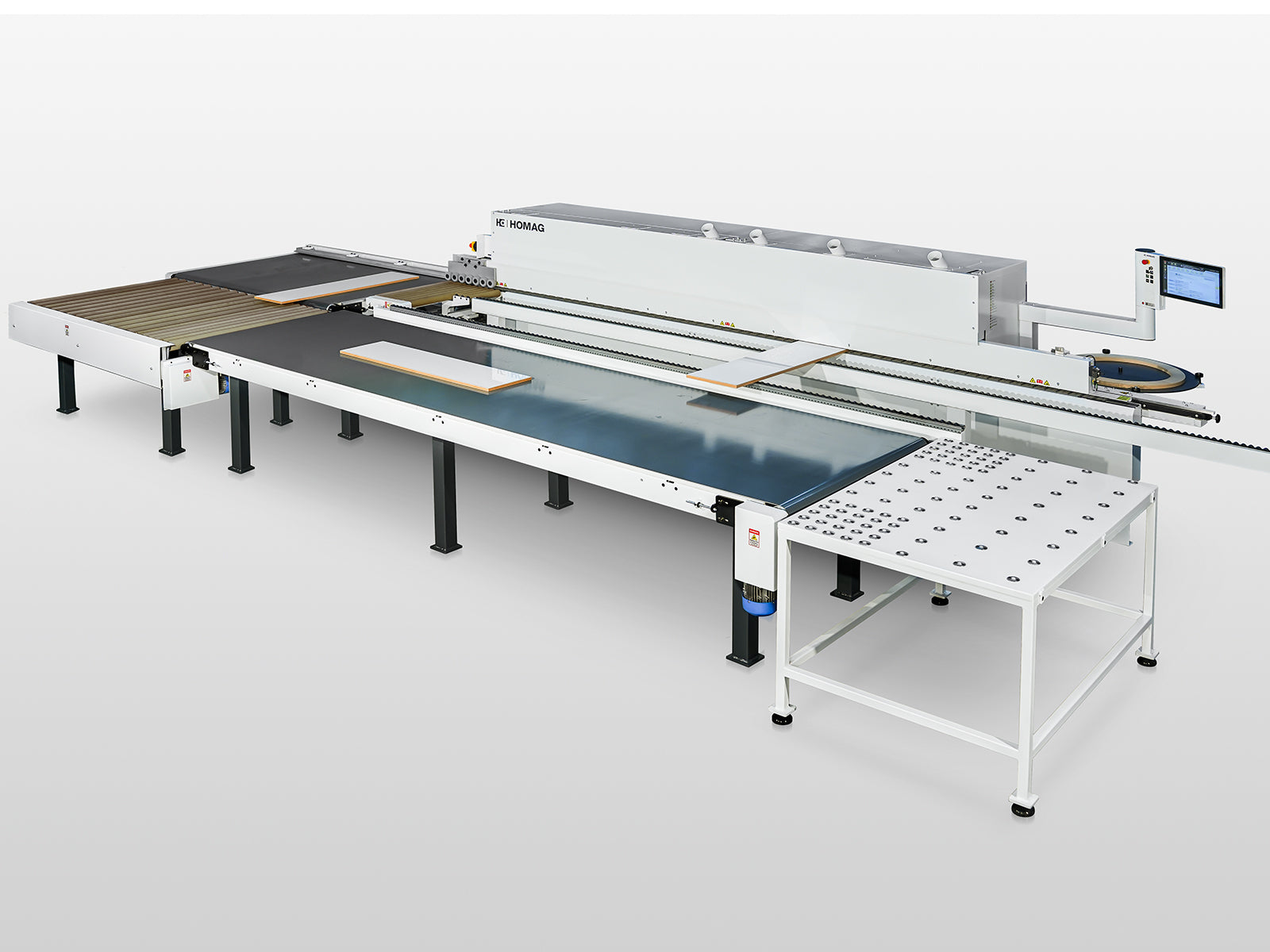

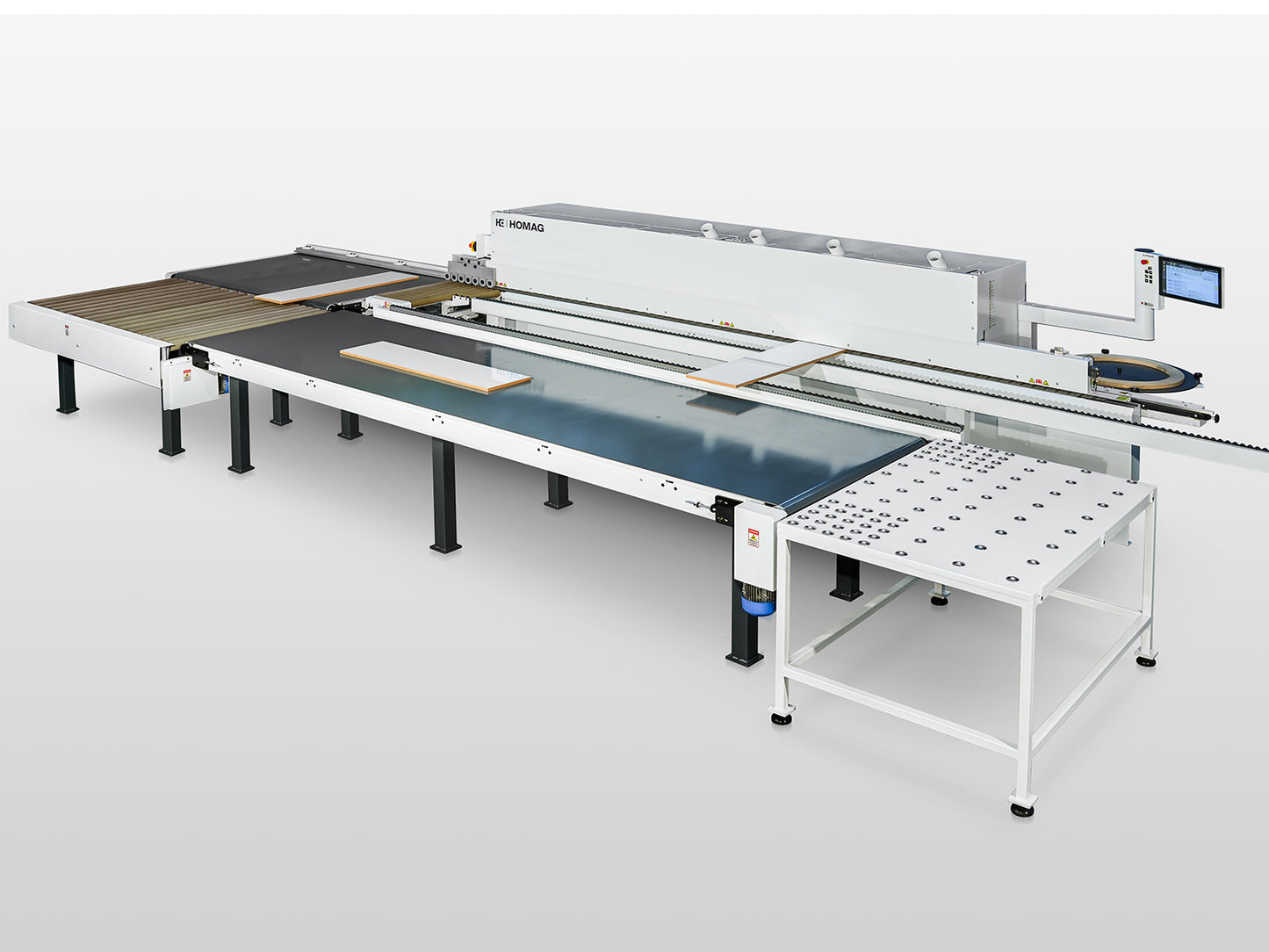

RCS 14

RCS 14

The return conveyor system RCS-14 is designed to automate the edge banding machine EDGETEQ S-230 and is an essential helper for more efficient edge banding of workpieces. The RCS-14 ensures that each finished workpiece returned to the operator without causing damage or defects. Having an adjustable conveyor speed of 8 - 14 m/min enables operators with more control over the edge banding process, enabling them to adjust the system as needed to optimize performance and throughput.

Share

Collapsible content

Production Description

The material flow is automated and ordered, making the edge banding machine more efficient. The result is a leaner and more efficient edging process with an ordered flow of parts for any production solution. Thanks to automation, one machine operator is sufficient for the complete processing of the workpieces. The automated parts flow is the decisive advantage over competitors who still feed workpieces in manually.

Highlights

- Increased efficiency - Reduction of labor costs.

- Flexible personnel organization — One-man operation

- Plug & Play operation — No training required

- Better quality control and process stability

- Ergonomic operation — Reduced operator fatigue

- Capacity availability at all times.

Benefits

Simple and Intuitive Controls

Sanding Heads

Technical Details

| Conveyor Speed | m/min | 8 -14 |

| Workpiece Length | mm | 300 - 2450 |

| Workpiece width | mm | 120 - 1450 |

| Thickness | mm | 8 - 50 |

| 4 side processing* | - | - |

| Minimum work piece size | mm | 300 x 300 |

| Maximum workpiece size | mm | 1450 x 1450 |

| Maximum workpiece weight | Kg | 50 |

| Mass / unit area | Kg/Sqm | 25 |

| Working Height | mm | 835 - 950 |

| Controls | - | Independent of machine controls with variable feed speed |

| Connected Load | KW | 2.5 |

| Electricals | - | 3ph, AC 400V, 50Hz |

| Control Voltage | V | 24 Vdc |

*User has to manually adjust the processing speed as per the speed of edge banding machine. There is no automatic synchronization of speed with edge banding machine.

**In four-sided processing, manual help required for parts with widths more than 1500mm. Increased loading gap required between workpieces of shorter length & longer width. Evaluate by trials for best results. Please refer to technical documentation for more information.

Features

- A unique combination of flat belt and rubber roller for effective transportation of panels

- Independent controls for plug & play operation

- Emergency stop button for safety

- 3 ply belt for effective gripping and transportation of panels

- Steel tubes molded with graded rubber rollers for the scratch-free movement of panels.

- High torque geared motors for long trouble-free service

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

RCS 14

The return conveyor system RCS-14 is designed to automate the edge banding machine EDGETEQ S-230 and is an essential helper for more efficient edge banding of workpieces. The RCS-14 ensures that each finished workpiece returned to the operator without causing damage or defects. Having an adjustable conveyor speed of 8 - 14 m/min enables operators with more control over the edge banding process, enabling them to adjust the system as needed to optimize performance and throughput.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.