EDGETEQ S-230/220C

EDGETEQ S-230/220C

The EDGETEQ S-230's features make it the preferred choice for those seeking superior performance, efficiency, and flexibility.

Share

Collapsible content

Production Description

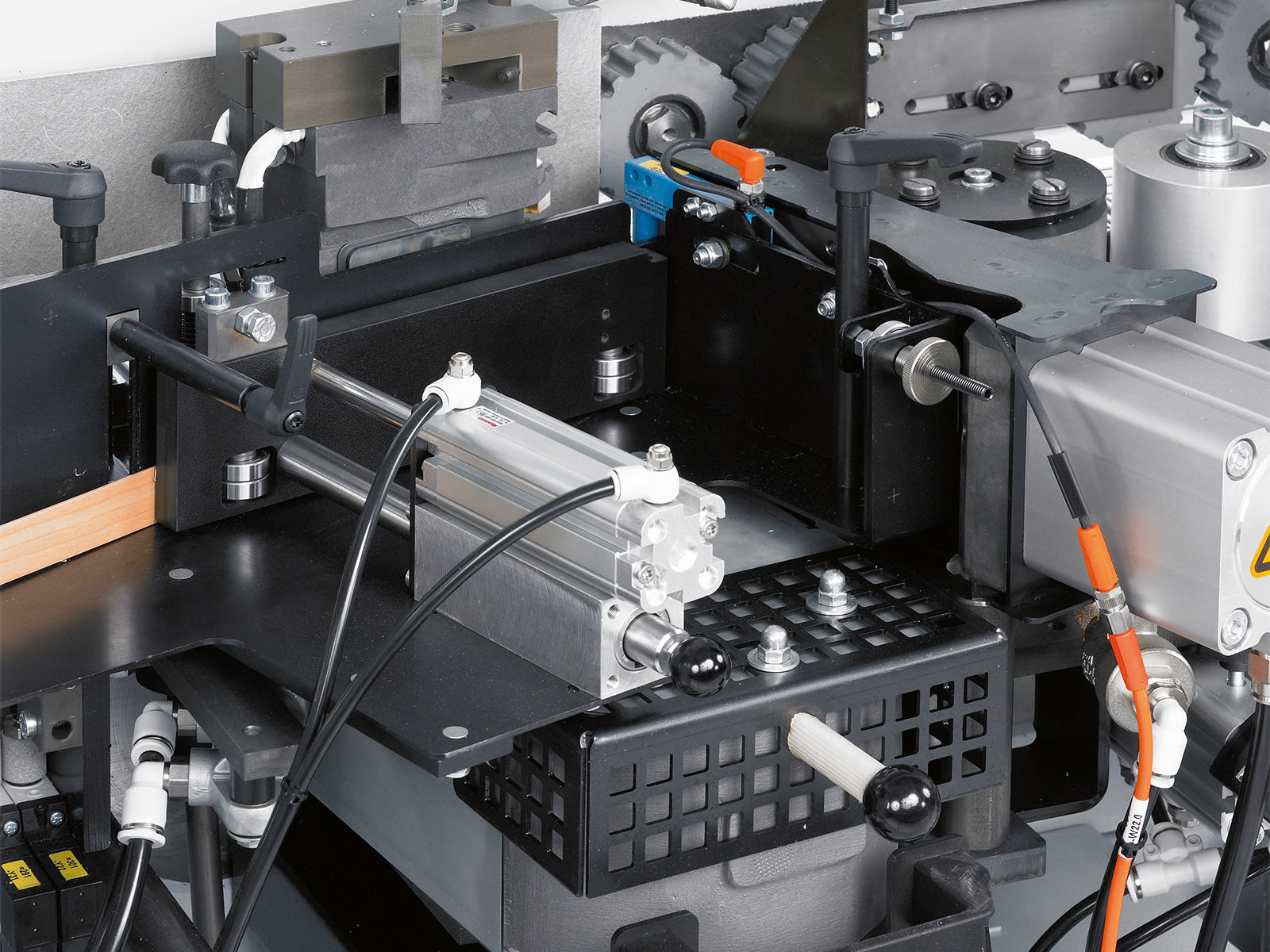

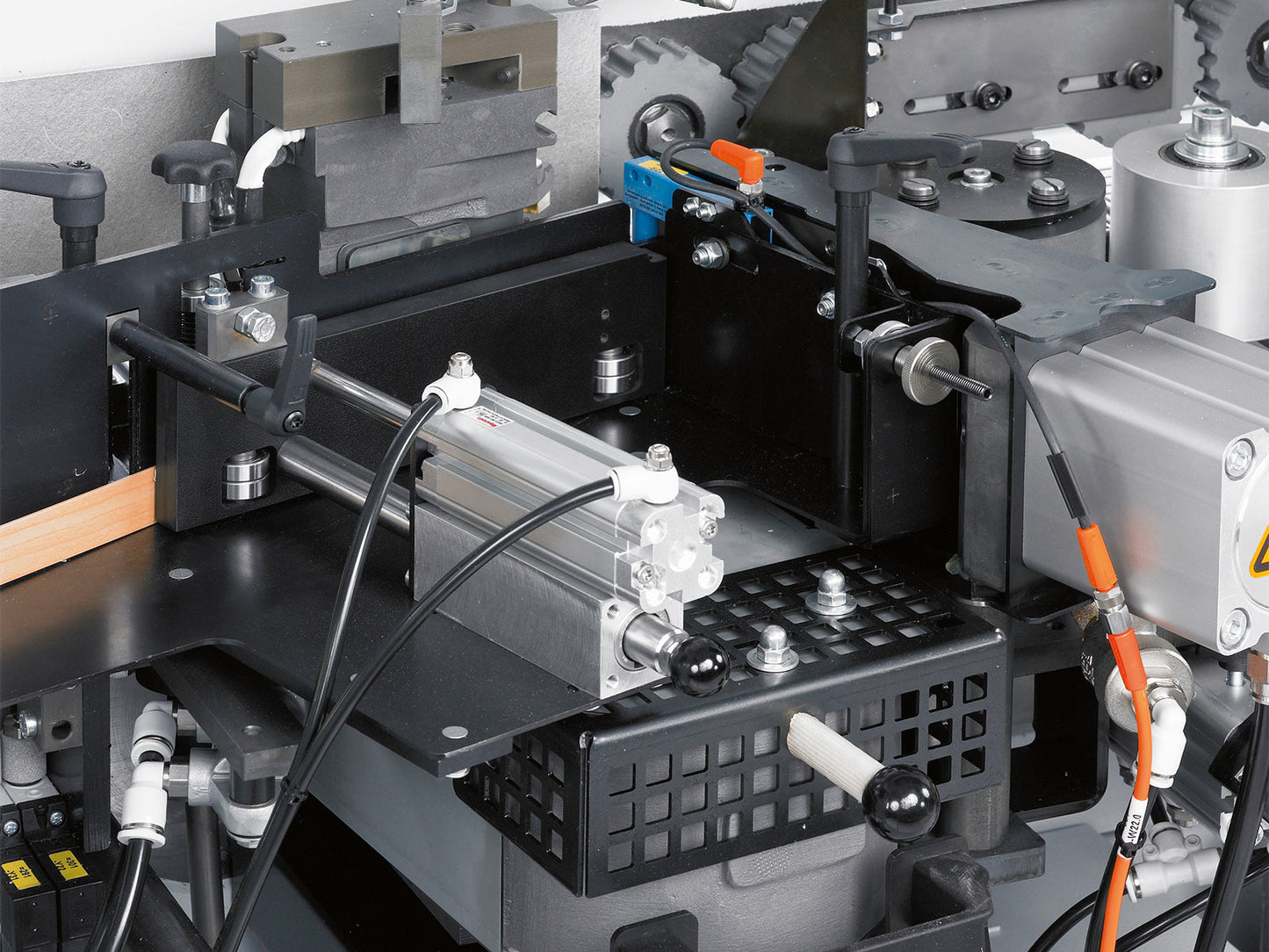

All machines of the EDGETEQ S-230 Series are equipped with a contact heating shoe that optionally activated transfers contact heat into the board edge directly prior to the glue application to the workpiece edge, this notably optimizing the gluing quality, especially with difficult edging materials or at very low ambient temperatures.

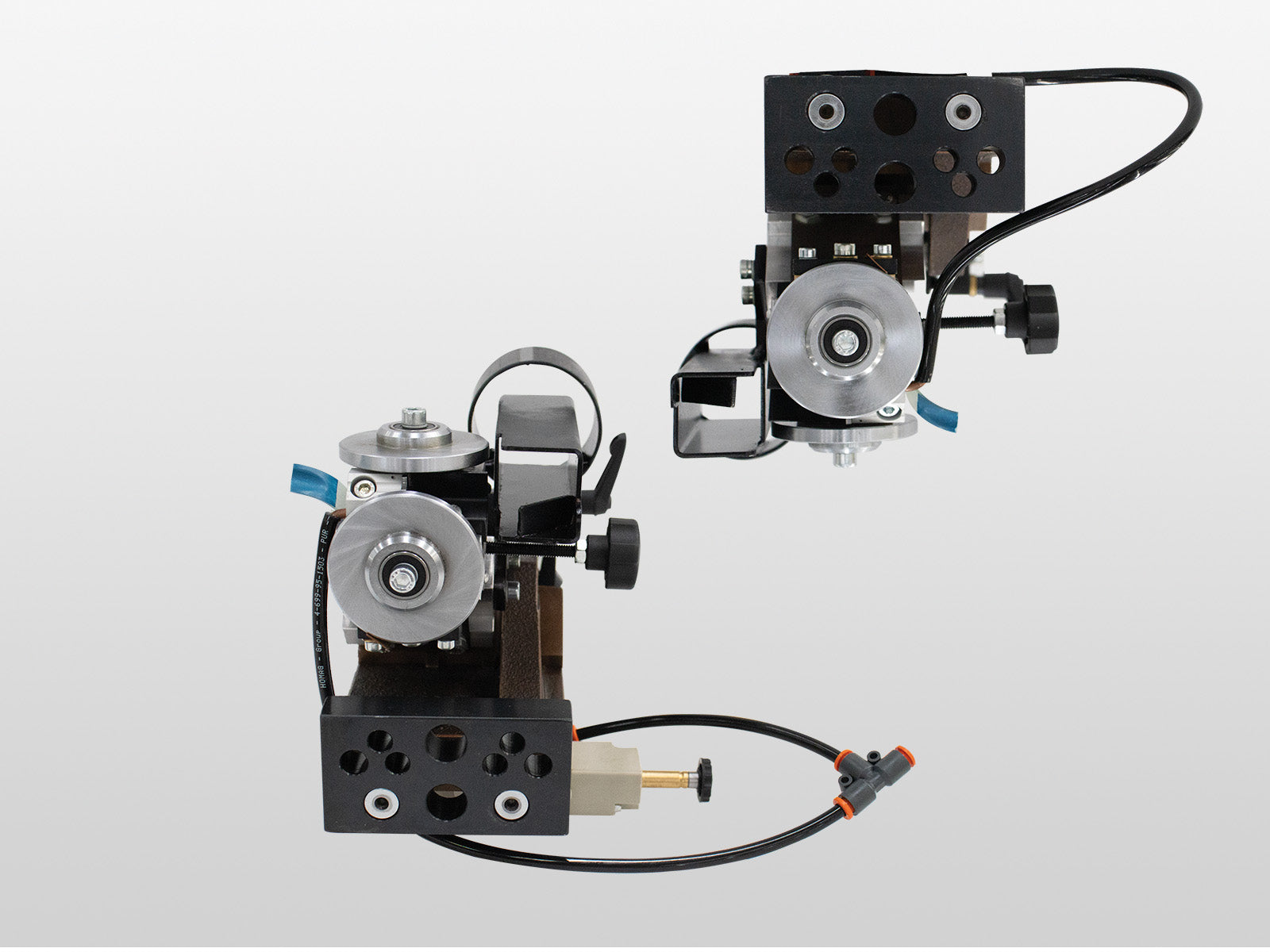

The Model 220 C is equipped with Gluing unit, Snipping unit, Trimming unit, Profile Scraper and Buffing unit. The operator set up the working units manually and precisely during the changeover of different thickness of edge materials and panel thickness. Starting from this we offer the EDGETEQ S-230 – Model 220 C with profile trimming unit which completes the corner rounding operation up to 40 mm panel thickness. Precise manual adjustment of the units ensures perfect finishing on top and bottom as well as corners on the edge material.

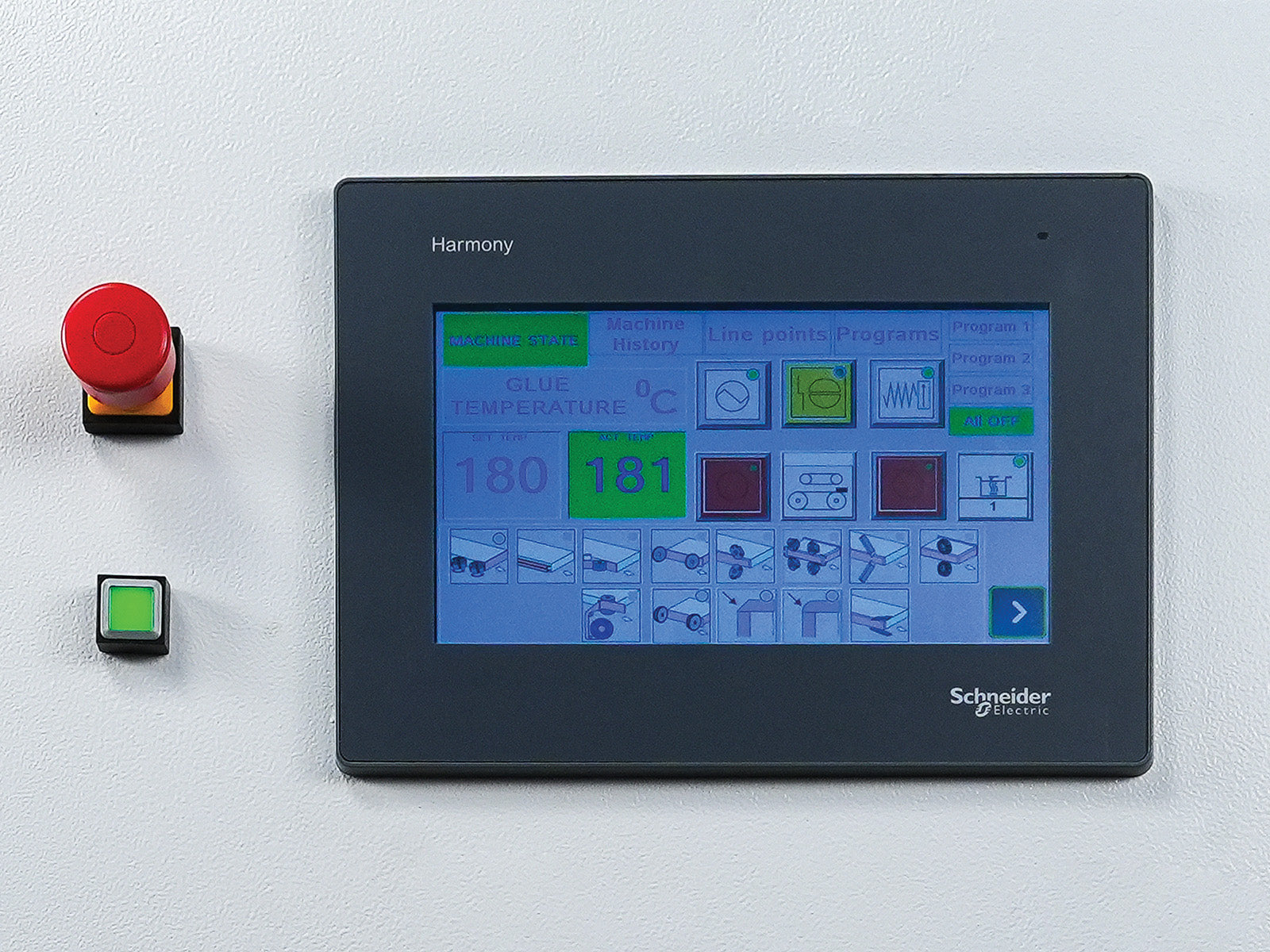

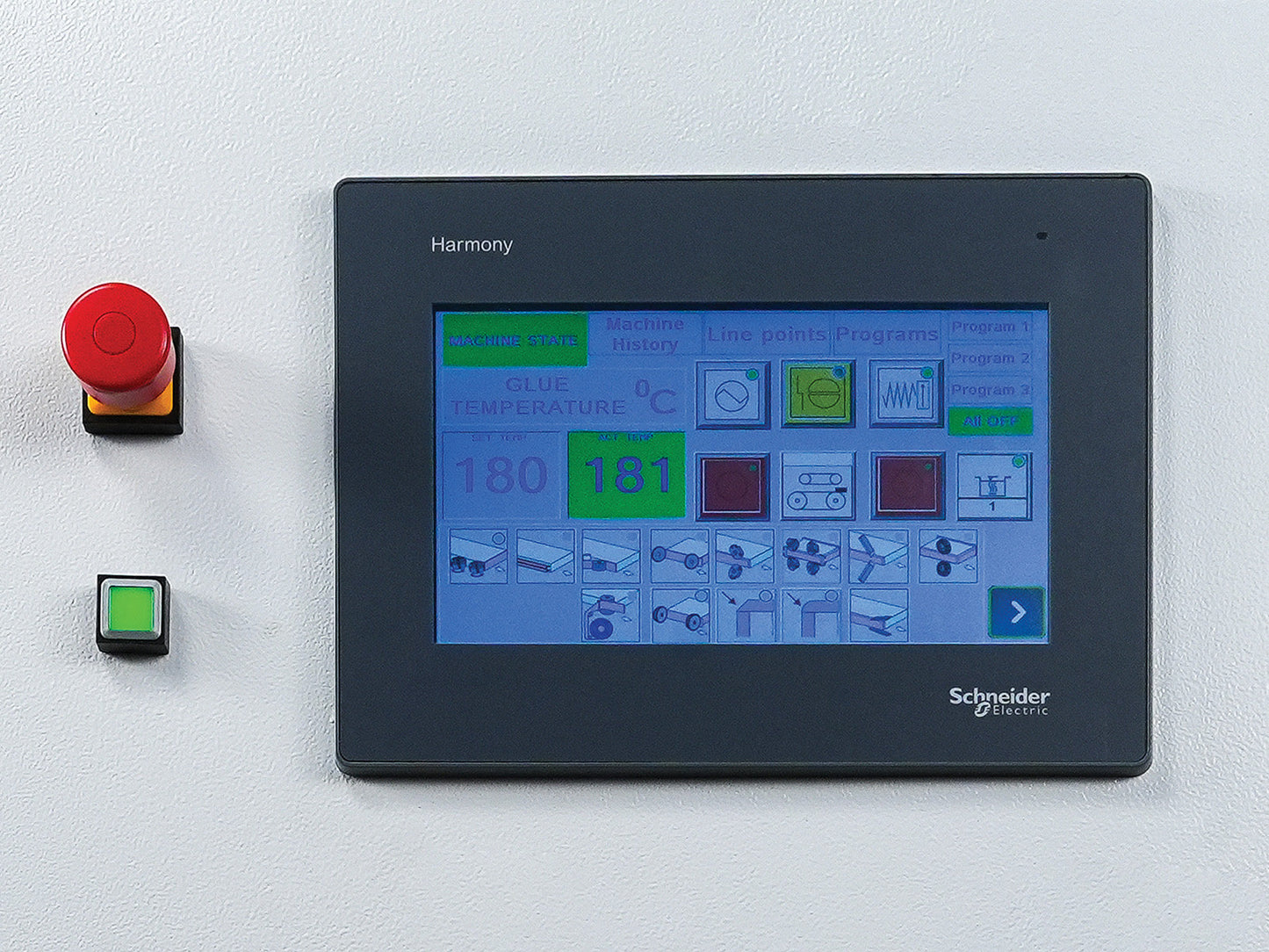

This machine is equipped with a with Touch HMI control system and provides high operating convenience through simple menu format and optimized line point adjustment.

The feed speed of EDGETEQ S-230 Model 220 C are 11 m/min.

Highlights

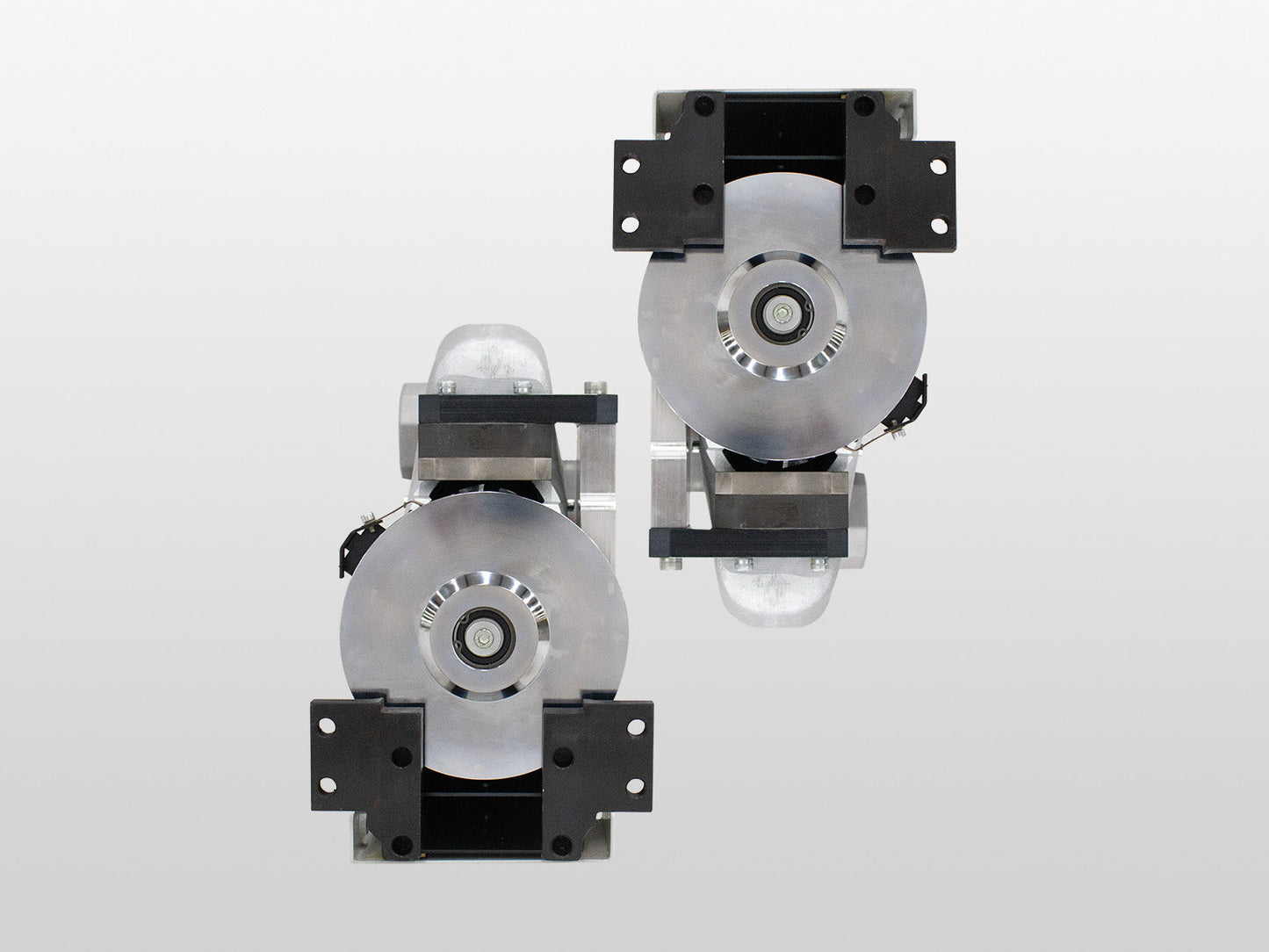

- Perfect cut and high operating life due to diamond tipped tools for an optimum edge joint quality.

- Counter pressure device magazine for sensitive edges.

- Coil and automatic strip magazine for a reliable edge material supply. Optimal glue joints, by controlling the exact amount of glue.

- Heavy pressure zone up to 3 mm edge thickness and 50 mm work piece height for an optimal glue joint.

- Precise end-cut through a strong end trimming unit, equipped with THK guides. Chamfer / straight adjustment by easily tilting the unit.

- Touch HMI controls for ease of operation

Benefits

Simple and Intuitive Controls

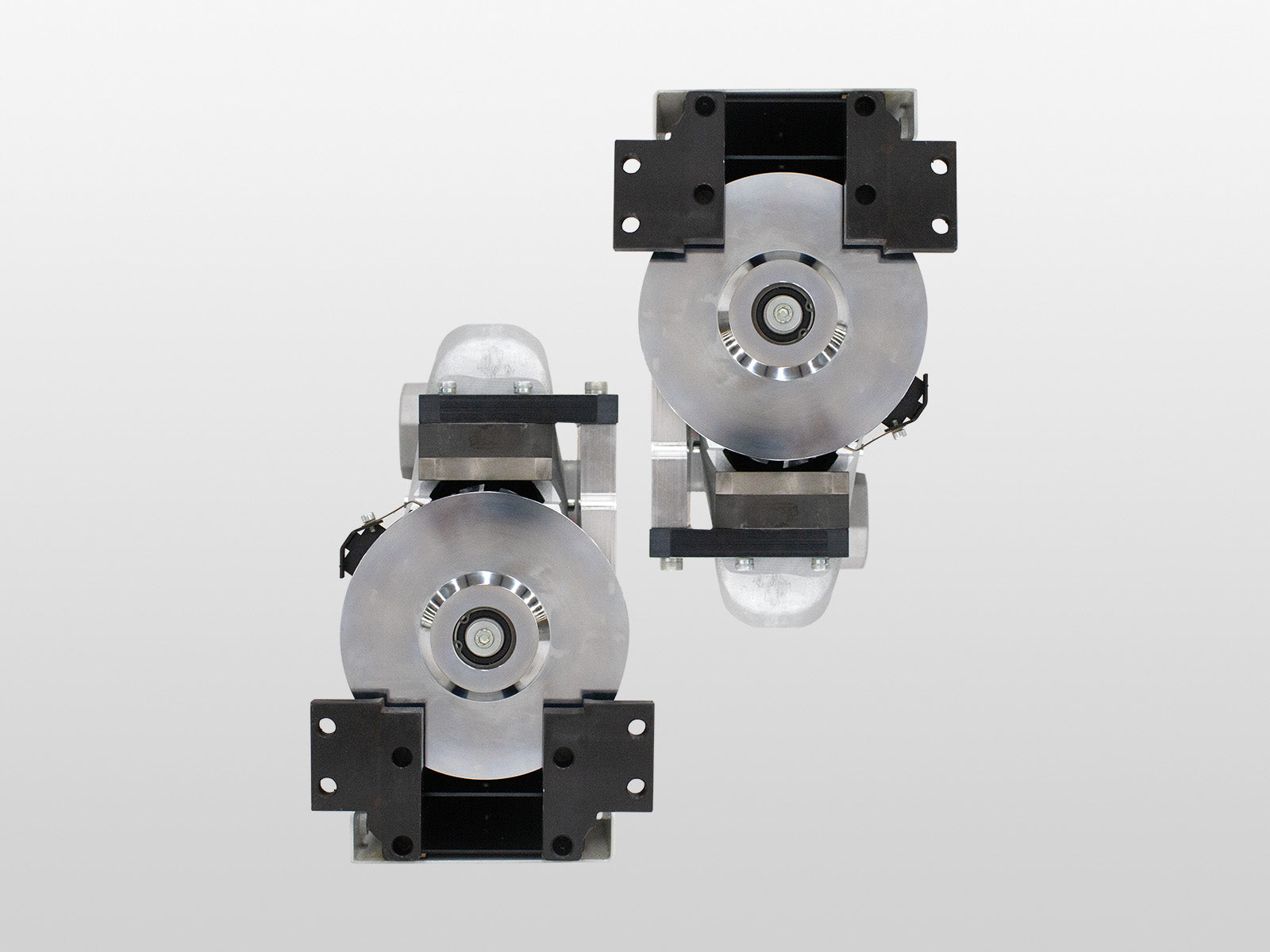

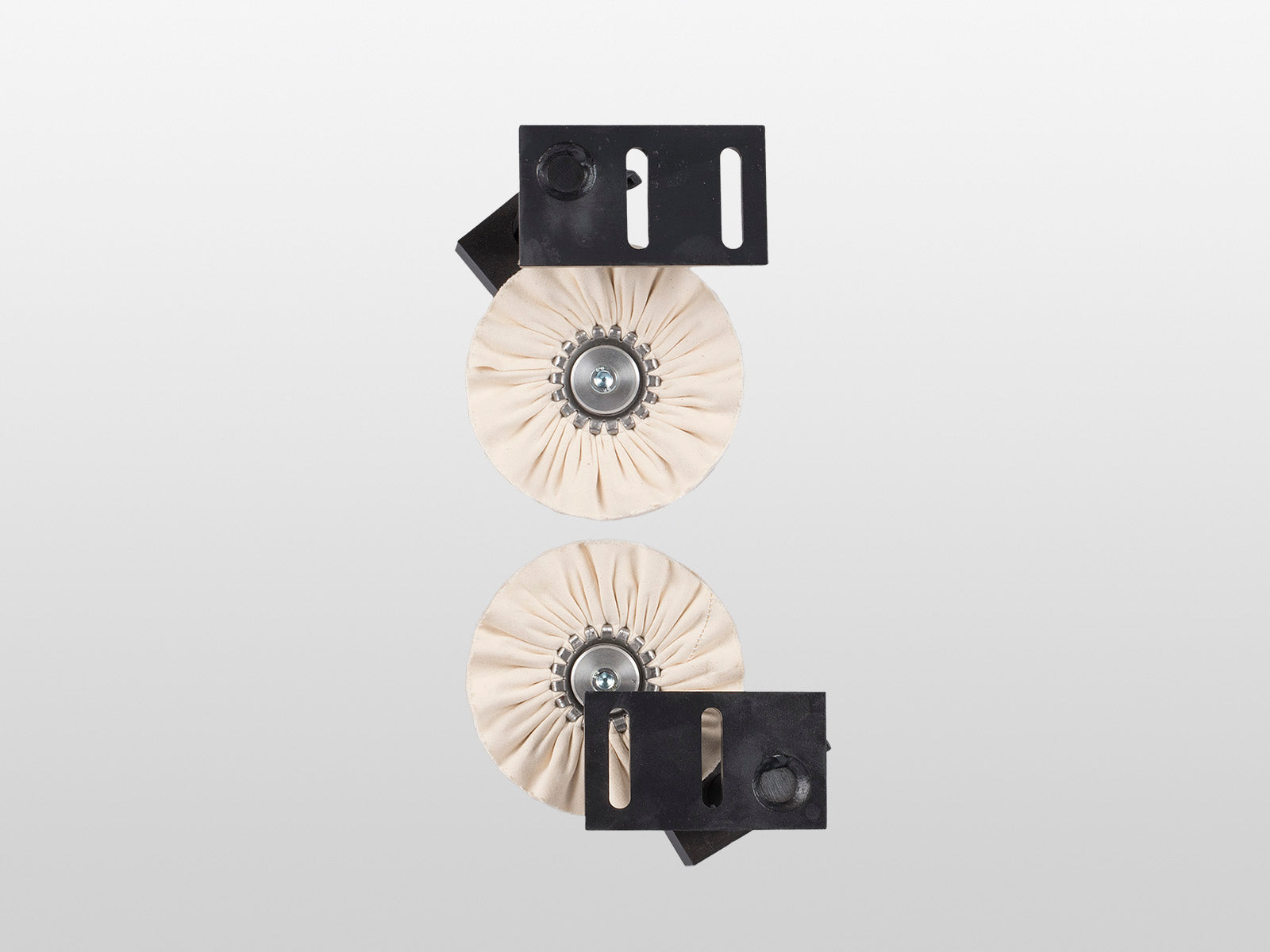

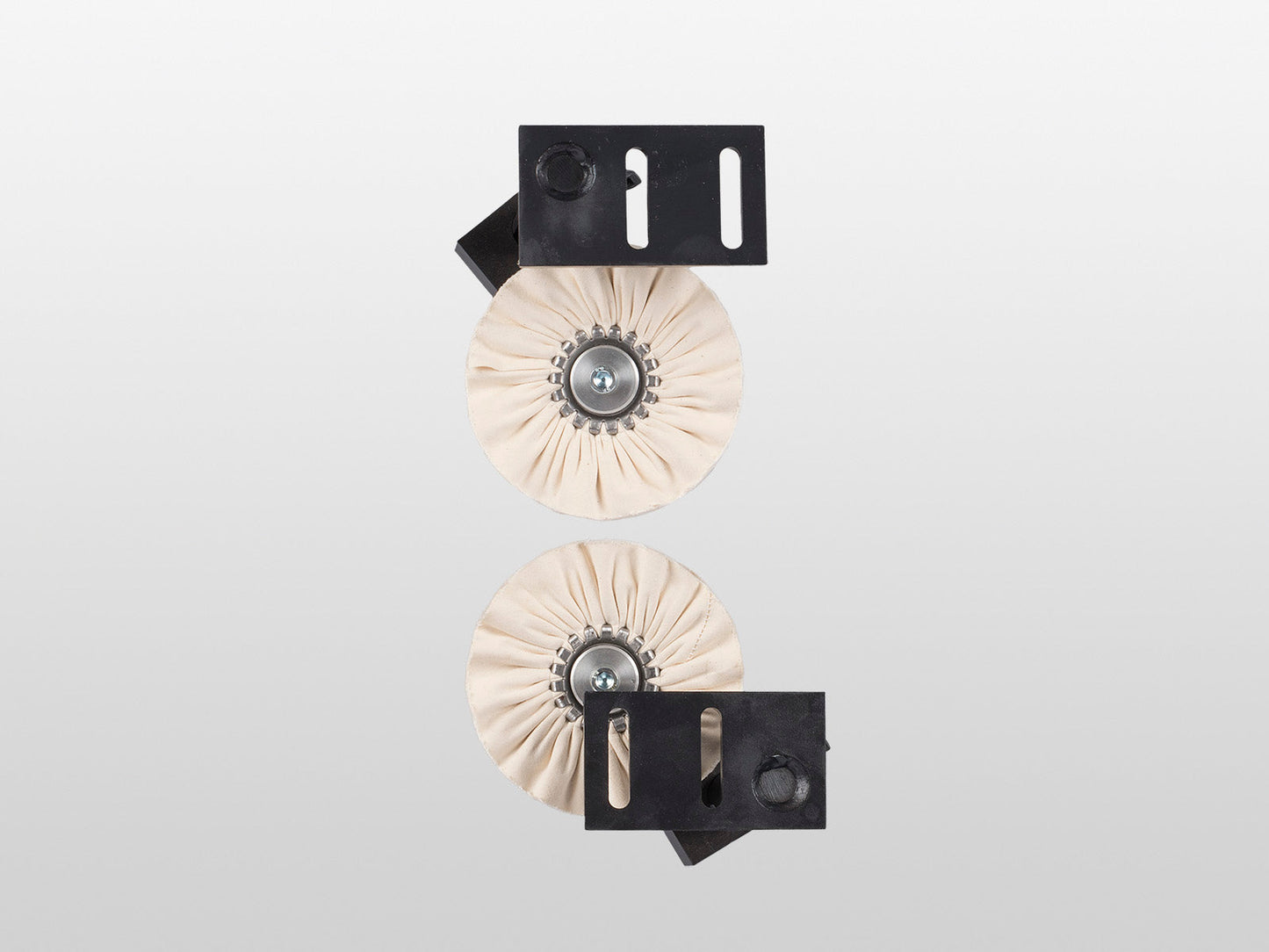

Sanding Heads

Technical Details

| TECHNICAL DETAILS | MODEL 220C | MODEL 220FC | MODEL 220FCP |

| Work Piece Thickness | 8 - 50 mm | 8 - 50 mm | 8 - 50 mm |

| Edge Material Thickness | 0.4 - 3 mm | 0.4 - 3 mm | 0.4 - 3 mm |

| Feed Speed | 11m / minute | 11m / minute | 11m / minute |

| Weight | 1260 KG | 1290 KG | 1290 KG |

| Collected Value | 5.5 KW | 10 KW | 10 KW |

| Extraction Diameter | 3x80, 1x100 mm | 3x80, 1x10, 1x120 mm | 3x80, 1x10, 1x120 mm |

| Electrics | 400V- 3Ph + N - 50Hz | 400V - 3Ph +N - 50Hz | 400V - 3Ph +N - 50Hz |

| Pneumatics | 6 bar | 6 bar | 6 bar |

| ISO 1827 -2015 Certification | X | X | |

| CE Certification | X |

Features

Model 220C Key Features

Starting from this, we offer the machine with contour trimming unit which completes the corner rounding operation up to 40 mm work piece thickness. Precise manual adjustment of the units ensures perfect finishing on top and bottom as well as corners on the edge material.

Model 220FC Key Features

The machine comes with the joint trimming unit, which removes the imperfection on the panels from the cutting process. The units are set by the operator using numerical indicators on each unit with the quick change from the thin edge to thick edge material.

Model 220FCP Key Features

The end trimming unit, profile trimming unit and profile scraper are managed automatically from 7’ touch HMI screen. The automatic change over in the working units makes the machine more flexible and efficient during frequent changeover as per production needs.

Machine Dimension

| Model | Length | Height | Width | Working Height |

| 220 C | 41500 mm | 2180 mm | 1300 mm | 950 mm |

| 220 FC | 41500 mm | 2180 mm | 1300 mm | 950 mm |

| 220 FCP | 41500 mm | 2180 mm | 1300 mm | 950 mm |

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

EDGETEQ S-230/220C

The HOMAG EDGETEQ S-230 NKR220C optimized edge banding technology with its performance, efficiency, and flexibility. It's comes with a glue application system that ensures optimal glue distribution and minimizes wastage. The glue is applied precisely to the panel edges, resulting in a secure and durable bond. The machine's efficient heating system facilitates quick bonding and faster production cycles, further boosting productivity and throughput. With its user-friendly interface and intuitive controls, the machine allows for quick and easy setup, reducing the time spent on manual adjustments.

The EDGETEQ S-230's features make it the preferred choice for those seeking superior performance, efficiency, and flexibility.

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.