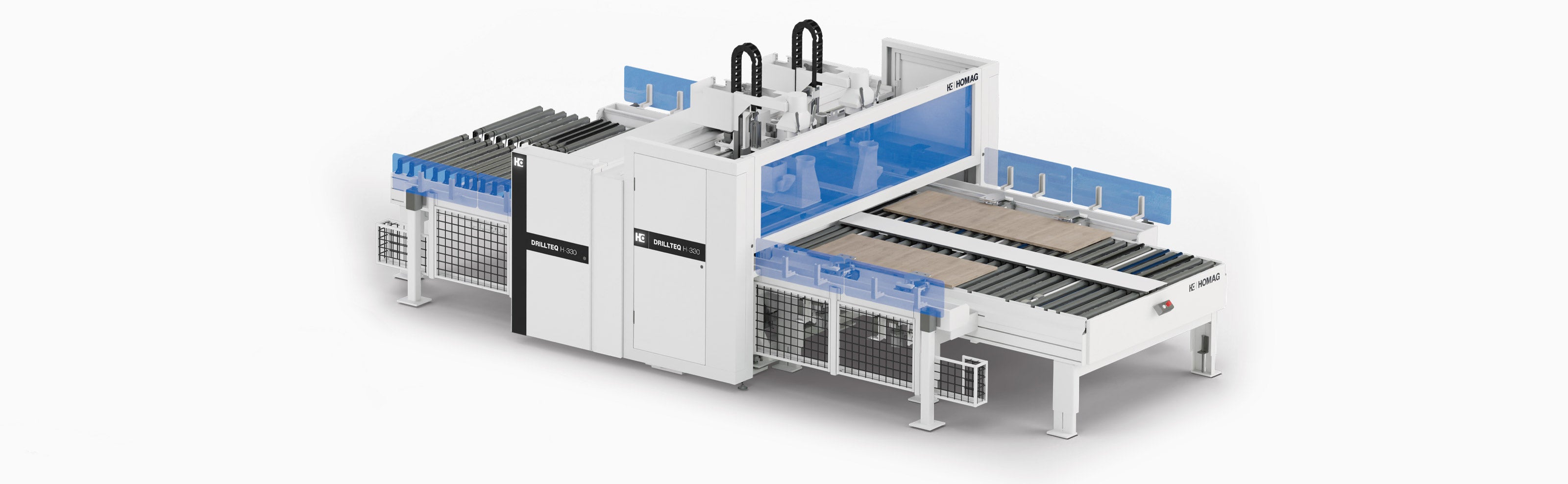

DRILLTEQ H-330

DRILLTEQ H-330

The DRILLTEQ H-330 impresses with speed and precision - in workpiece handling as well as in machining. Every drilling and milling operation is set with extreme repeat accuracy. The workpiece surfaces are perfectly protected despite fast processing speeds. The possibility of processing two workpieces at the same time results in double efficiency and the versatile connection options of the machine bring high flexibility.

Share

Collapsible content

Production Description

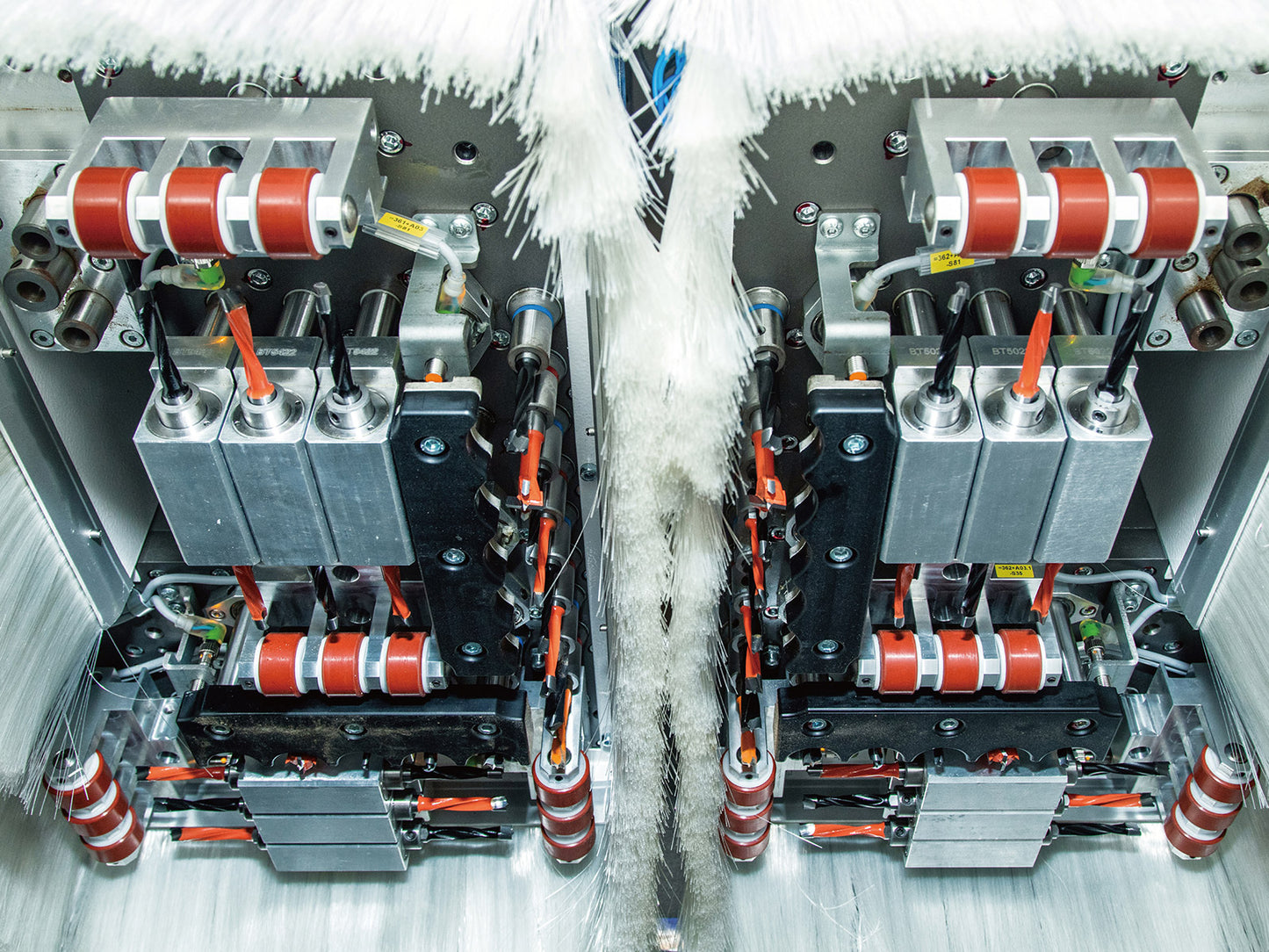

The 6-side drilling series DRILLTEQ H-330 impress with speed and precision - in workpiece handling as well as in machining. Every drilling and milling operation is set with extreme repeat accuracy. The workpiece surfaces are perfectly protected despite fast processing speeds. The possibility of processing two workpieces at the same time results in double efficiency and the versatile connection options of the machine bring high flexibility. With our single-channel and double channel 6-sided drilling series, we provide the perfect solution for your wishes and requirements

Highlights

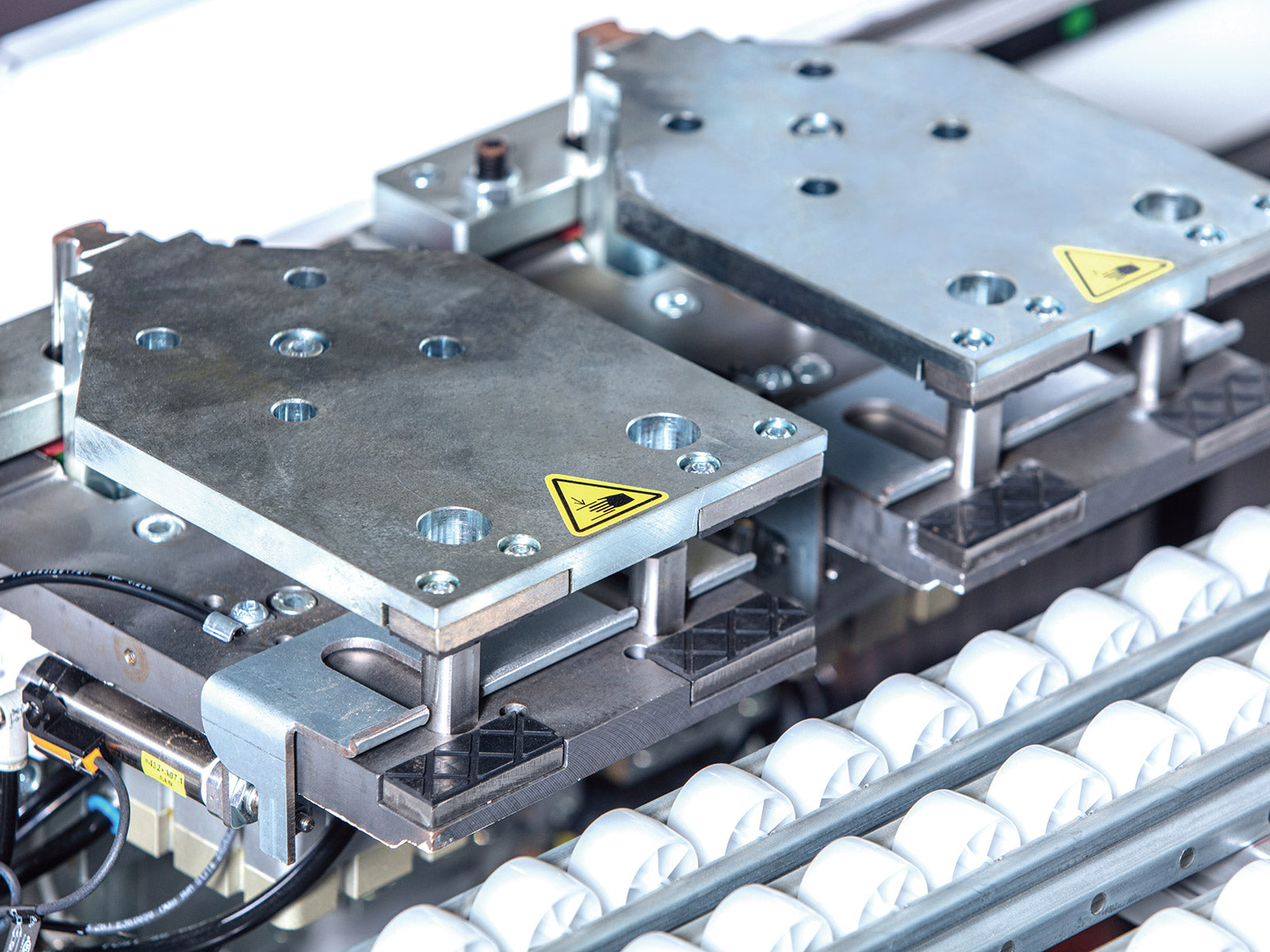

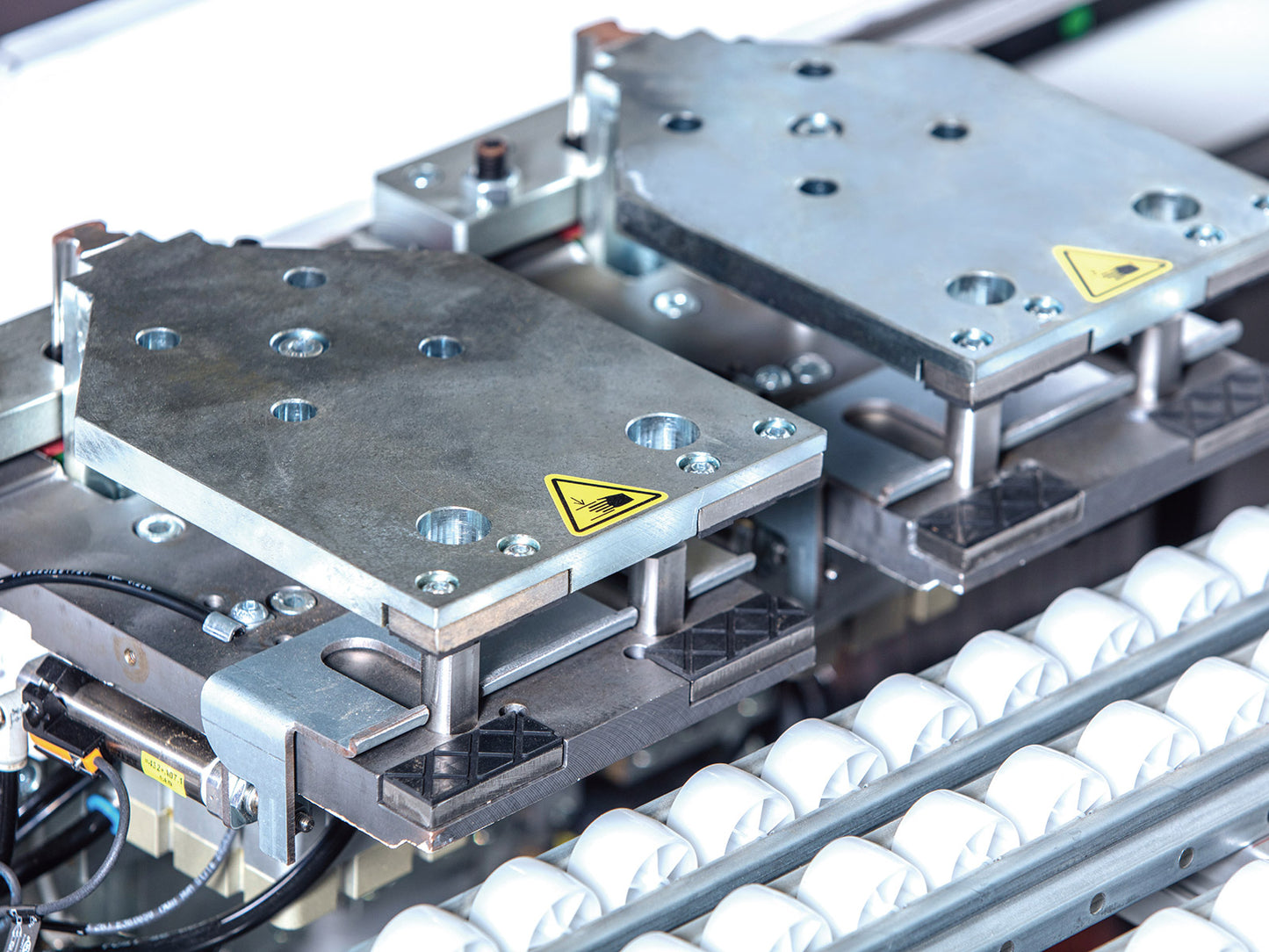

- CNC-controlled clamping system on both sides enables quick and precise drilling with no setting times2 CNC-controlled clamping devices ensure permanently firm and precise positioning of the workpieces – regardless of the speedwoodWOP software

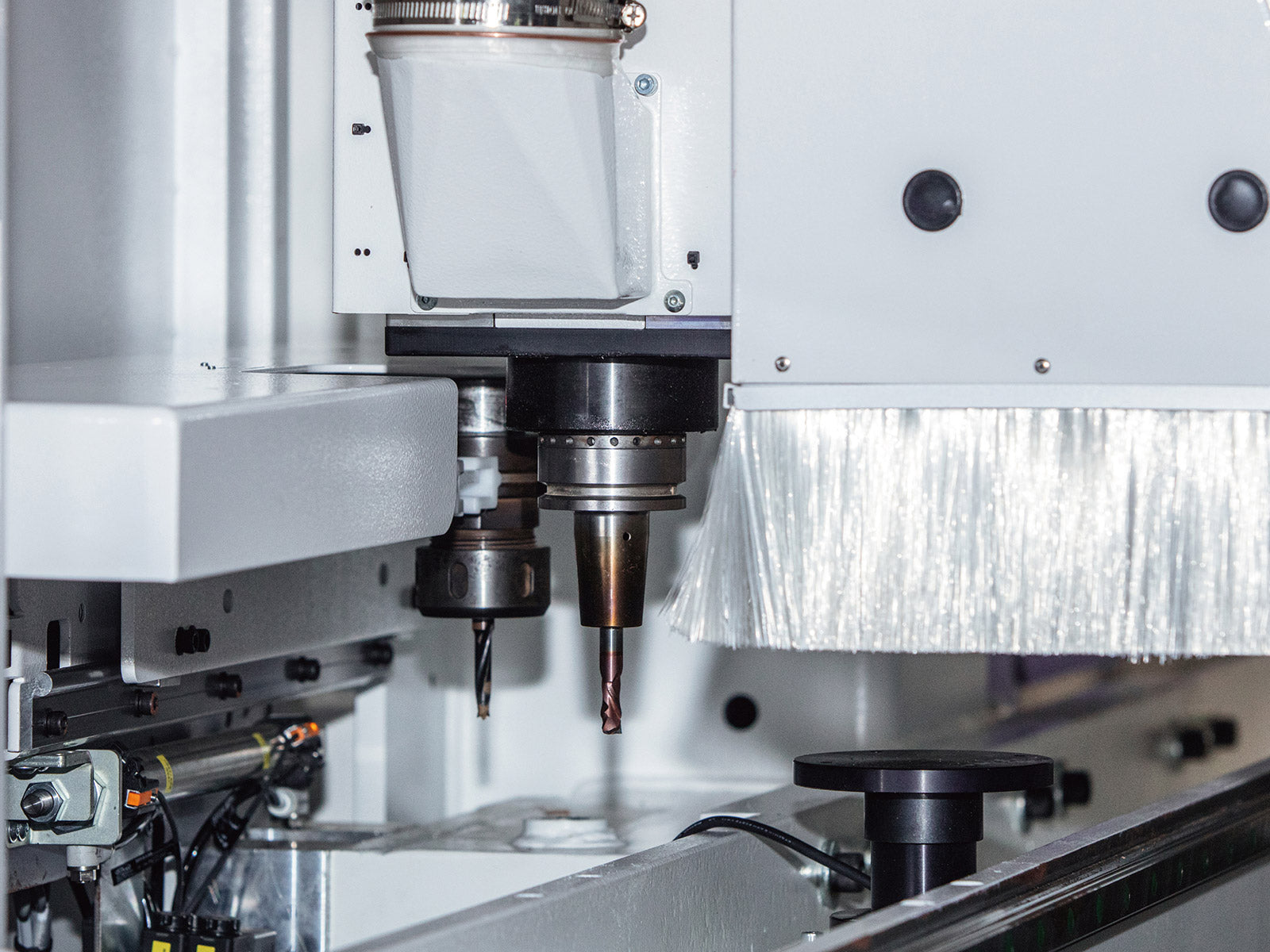

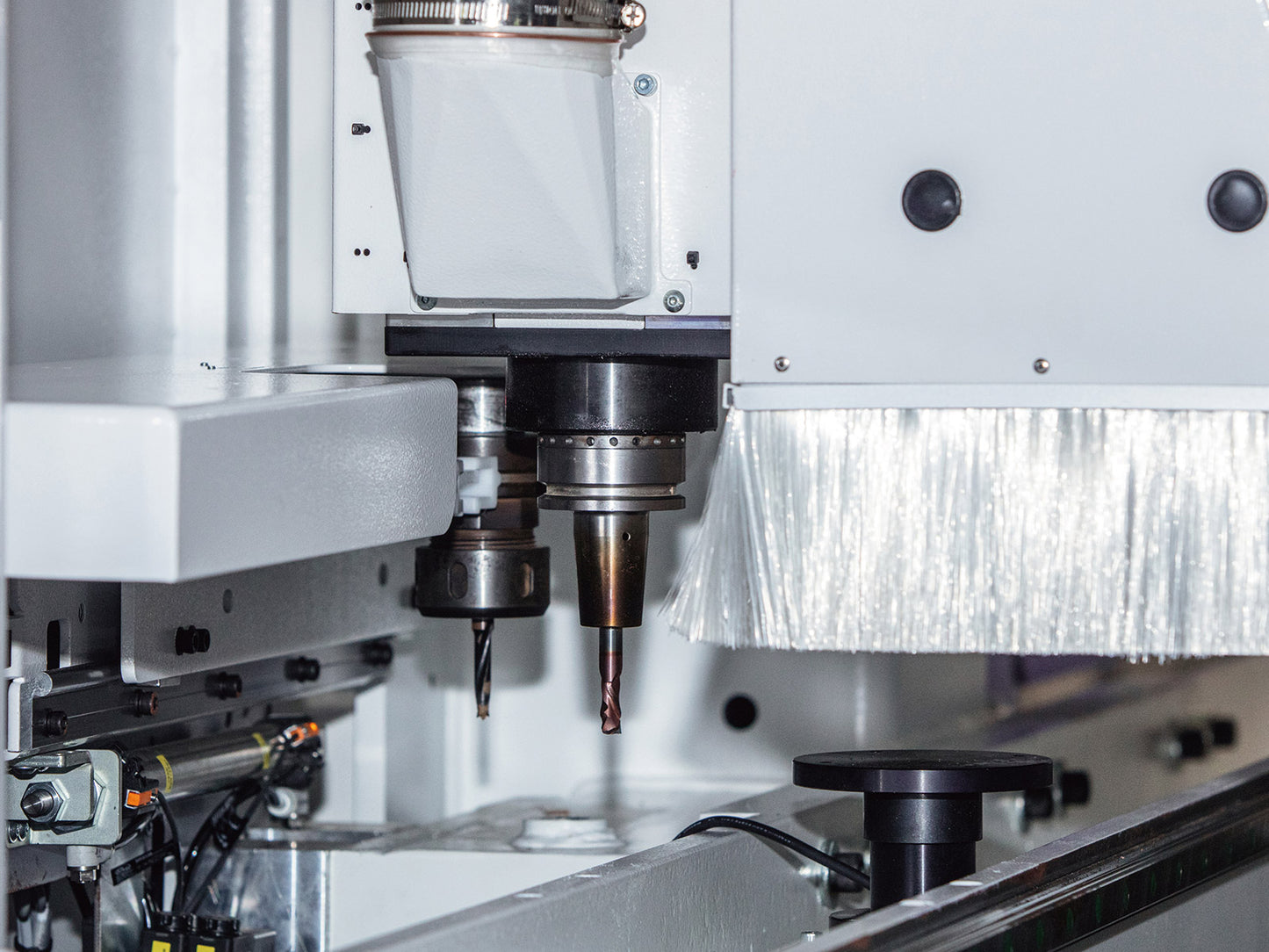

- High Speed Processing Unit | Top Head | High Speed 7500

- High Speed Processing Unit | Bottom V14, Router 3.5KW

-

Enjoy the benefits of faster, clearer and more comfortable interface with further improved powerTouch user interface

Benefits

Simple and Intuitive Controls

Sanding Heads

Technical Details

| FOOTPRINT | ||

| L | MM | 6000 / 7200 |

| W | MM | 3600 |

| H | MM | 2550 |

| WORK PIECE DIMENSION | ||

| Length | MM | 250 - 3000 |

| Width (single parts) | MM | 60 (40) - 1250 |

| Width (double parts) | MM | 2 x 620 |

| Height | MM | 8 - 40 |

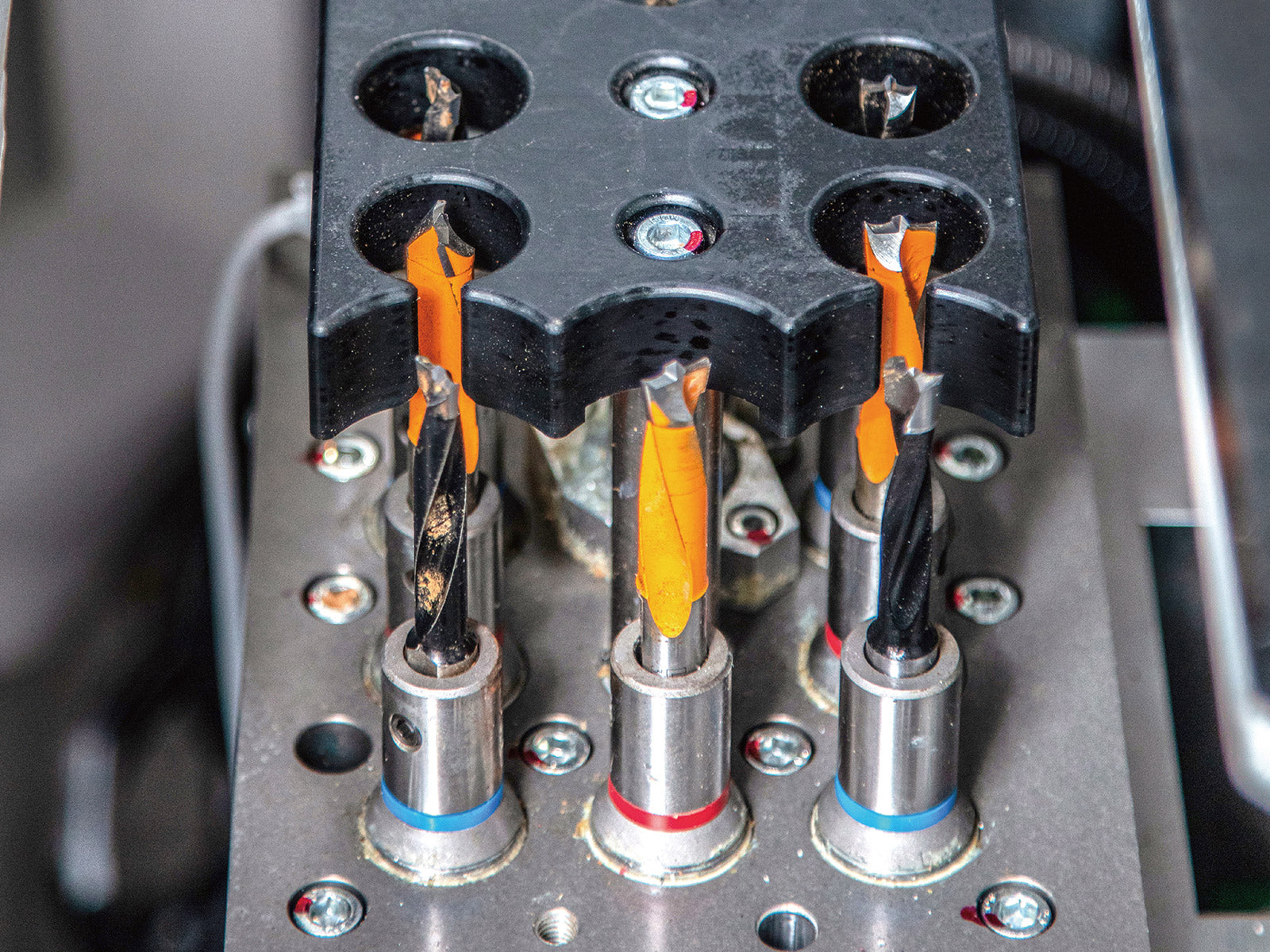

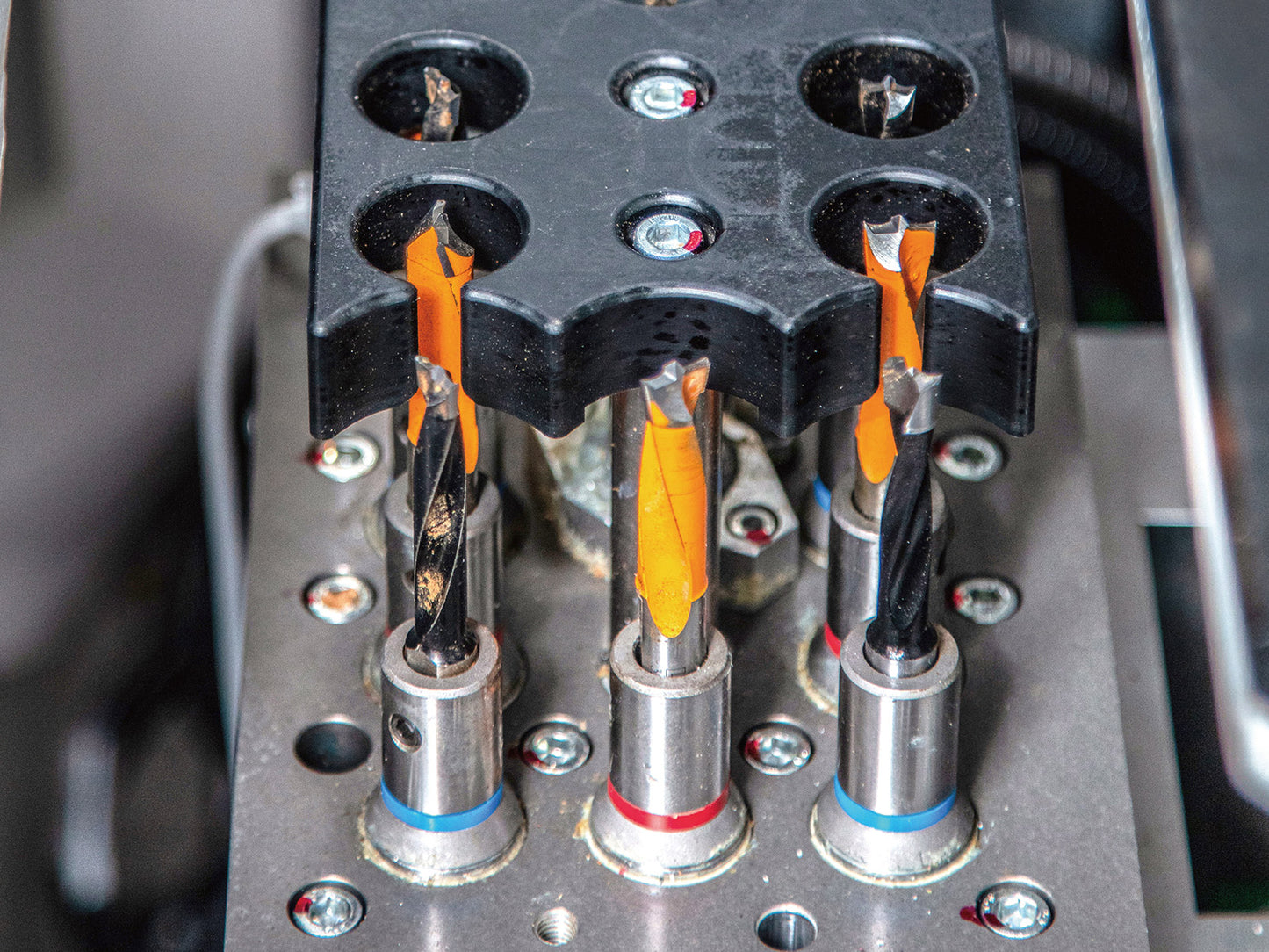

| DRILLING HEAD - TOP | ||

| Vertical Spindles | Qty. | 2 X 13 |

| Vertical Spindle Clamping | Patented | Yes |

| Horizontal spindles in X+/X- | Qty. | 2 x (3X+-/3X-) |

| Horizontal spindles in Y+/Y- | Qty. | 2 x {2Y+/2Y-) |

| Frequency controlled | RPM | 1250 - 7500 |

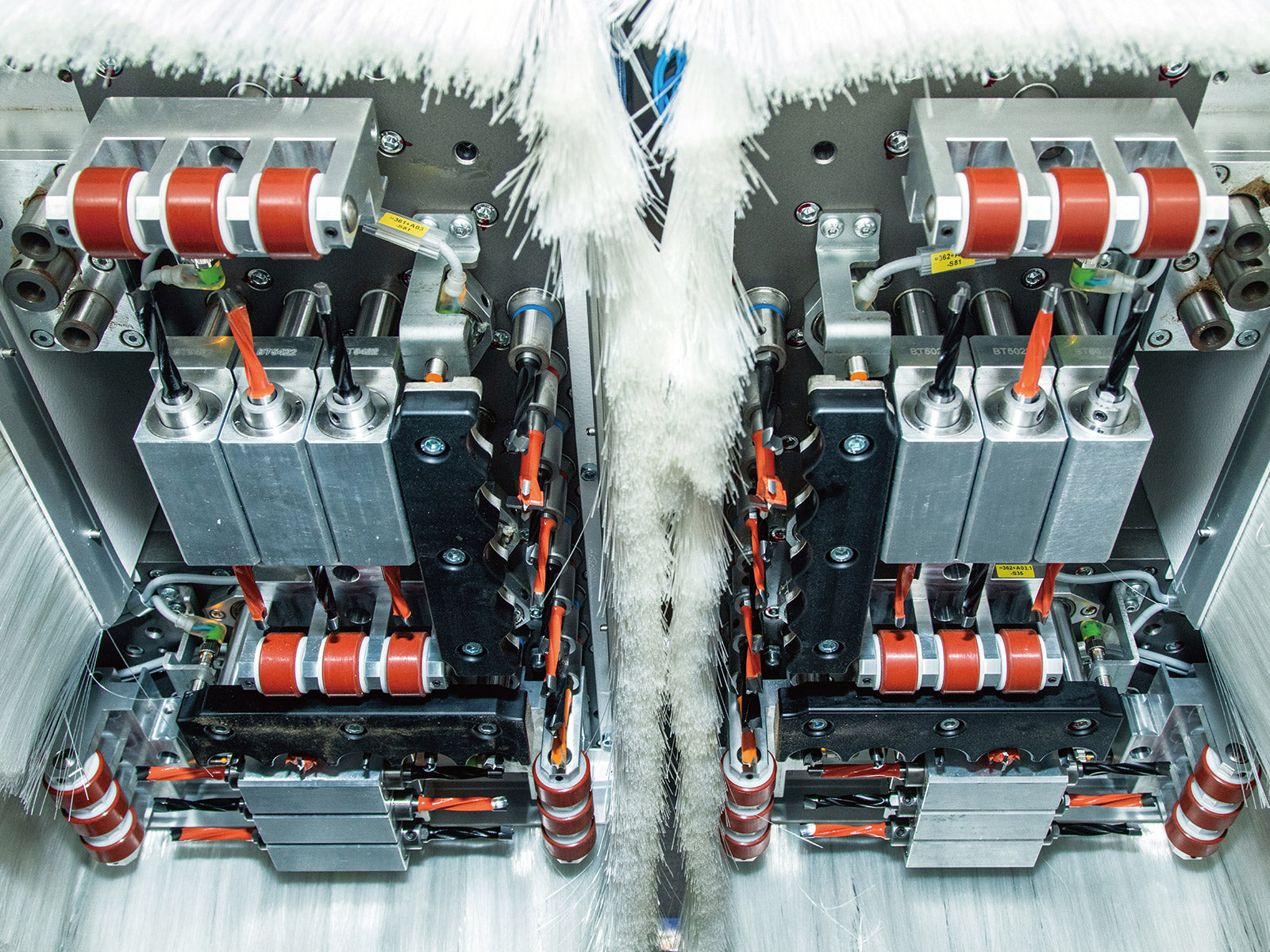

| DRILLING HEAD - BOTTOM 1 & 2 | ||

| Vertical spindles | Qty. | 2 x 8 |

| Vertical spindle clamping | Yes | |

| Frequency controlled | RPM | 1250 - 7500 |

| ROUTER | ||

| Frequency controlled | RPM | 18000 |

| Power | KW | 3.5 |

| Collet | Type | ER25 |

| SPINDLE FOR AUTO TOOL CHANGE | ||

| Frequency controlled | RPM | 24000 |

| Power | KW | 4.5 |

| Collet | Type | HSK-F63 |

| TOOL CHANGER | ||

| Type | Linear | |

| Fold | Qty. | 4 |

| Max. tool weight | kg | 5 |

Features

- 6 sided-processing along Operation on two working fields for a continuously processing of panels

- 4 CNC-controlled clamping devices ensure permanently firm and precise positioning of the workpieces – regardless of the speed

- workpieces – regardless of the speedEven workpiece dimensions of Length 250-3,000 and width 60(40)-1,250 mm are easy to handle

- Even workpiece dimensions of Length 250-3000 and width 60(40)-1250 mm (2 x 620 mm) are easy to handle

- The patented spindle clamp ensures an always accurate drilling depth for all drilling

- Optional top electric spindles with automatic tool changer make processing more possiblities.

-

Optional top electric spindles with automatic tool changer make processing more possiblities.

Machine Dimension

Download Brochure

Book a live presentation

Book your appointment and experience your solution live in action. As an on-site event in our showroom or as an online event from the comfort of your home. We will advise you to your personalized requirements. The choice is yours!

DRILLTEQ H-330

The 6-side drilling series DRILLTEQ H-330 impress with speed and precision - in workpiece handling as well as in machining. Every drilling and milling operation is set with extreme repeat accuracy. The workpiece surfaces are perfectly protected despite fast processing speeds. The possibility of processing two workpieces at the same time results in double efficiency and the versatile connection options of the machine bring high flexibility. With our single-channel and double channel 6-sided drilling series, we provide the perfect solution for your wishes and requirements

Contact

Our newsletter: Keep up to date!

What's new? Find out with just one click - each month you will receive the latest information on market trends, product news and developments, trade fairs and our customers' experiences.